A l’occasion des Audi Electric Days j’ai fait une « petite » compil e-tron comme je n’ai pas encore eu l’occasion de publier aucun communiqué de presse sur ces modèles. J’avais fait mes devoirs en allant rechercher tous les communiqués de presse et les photos, avant de participer à l’évènement d’ouverture des Audi Electric Days organisés par le groupe Autosphere dans la région liégeoise ce 16 septembre 2021. Je publie aux dates d’origines des communiqués de presse, en actualisant avec la date de mise à jour.

3 jours, 2 soirées, plus de 15 pages sur les sites presse BE/FR/DE, plus de 2400 photos de presse, une centaine de photos perso et voilà le résultat, dans ces 4 articles :

Dossier Audi e-tron partie 1 : l’e-tron, l’e-tron Sportback, et leurs déclinaisons S

Dossier Audi e-tron partie 2 : e-tron GT et RS e-tron GT

Dossier Audi e-tron partie 3 : Q4 & Q4 Sportback

Audi Electric Days by Autosphere

Sommaire

Dossier de presse complet

e-tron GT

Extérieur

Intérieur

Video de la production

Construction

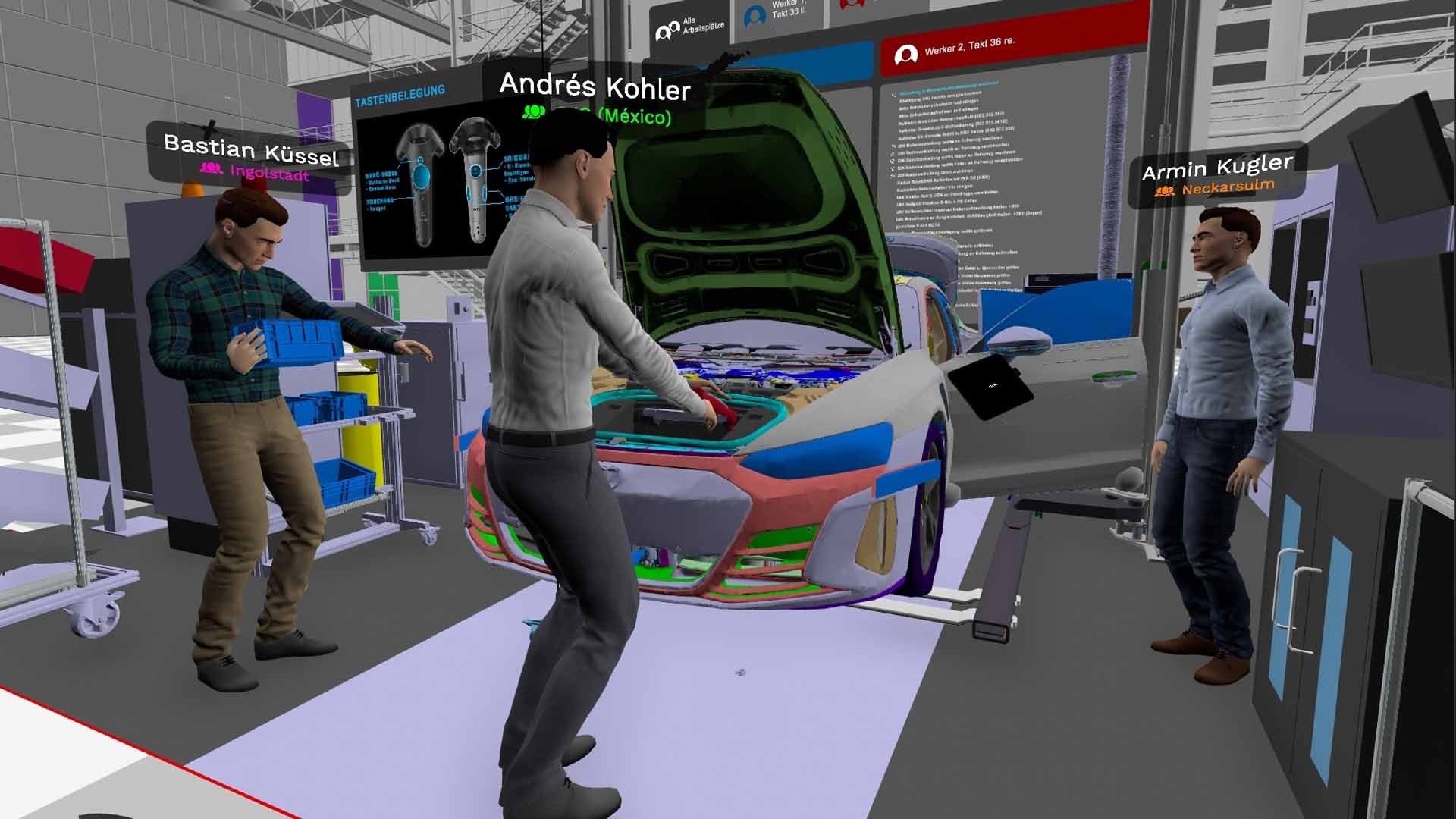

As part of a pilot project, , the logistics planners in Neckarsulm are currently testing how special containers can be planned and tested entirely in a virtual space and without any physical prototypes.

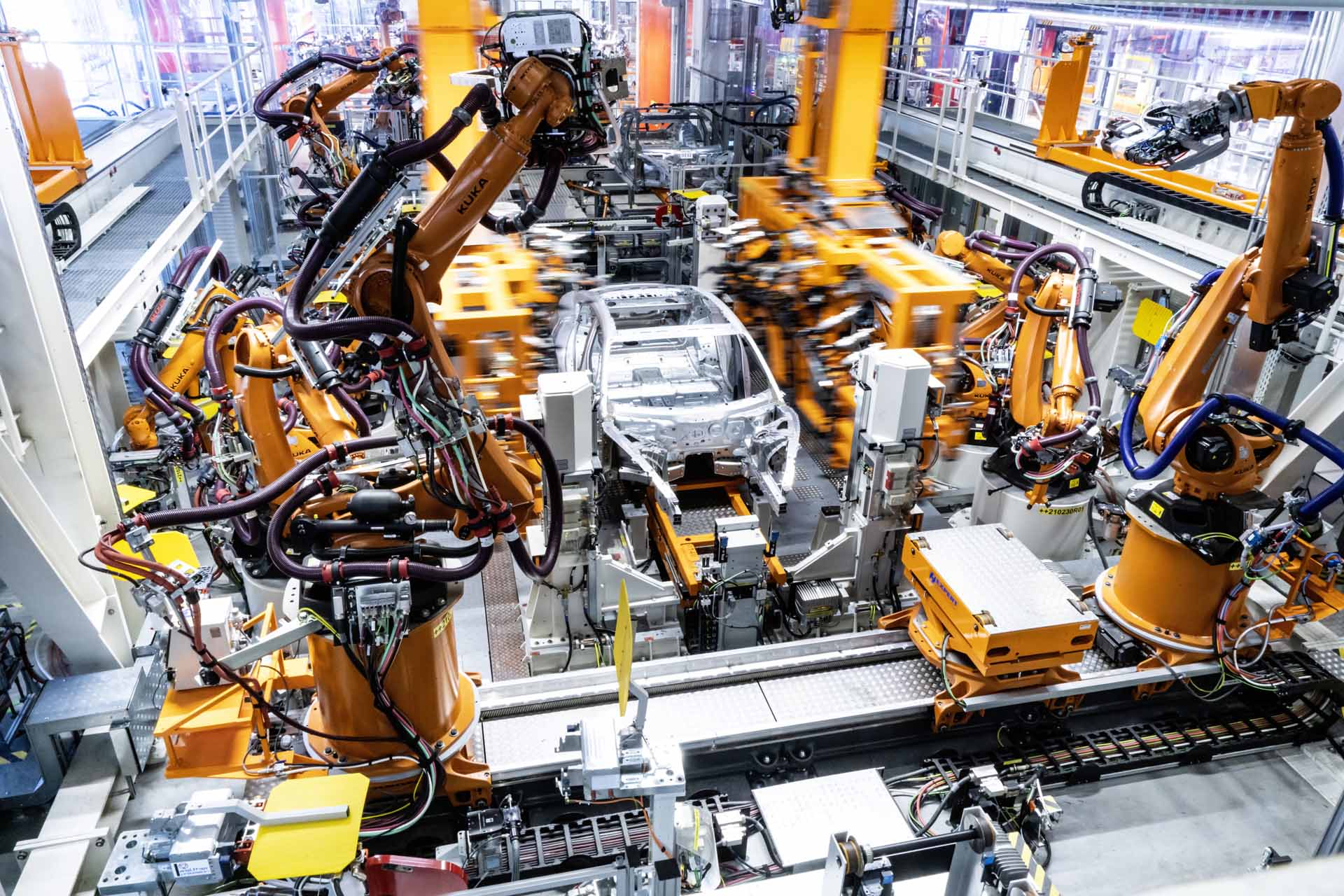

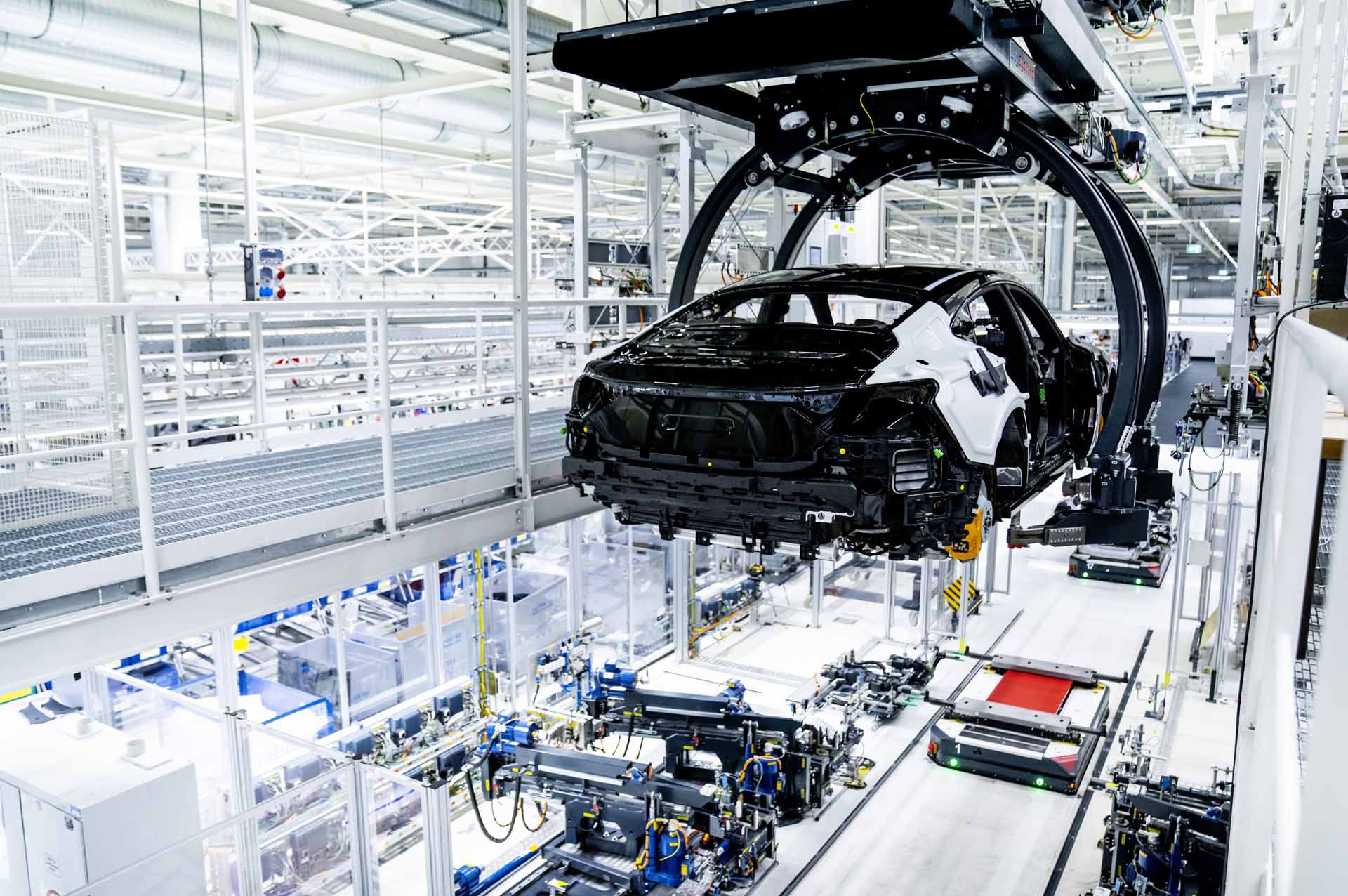

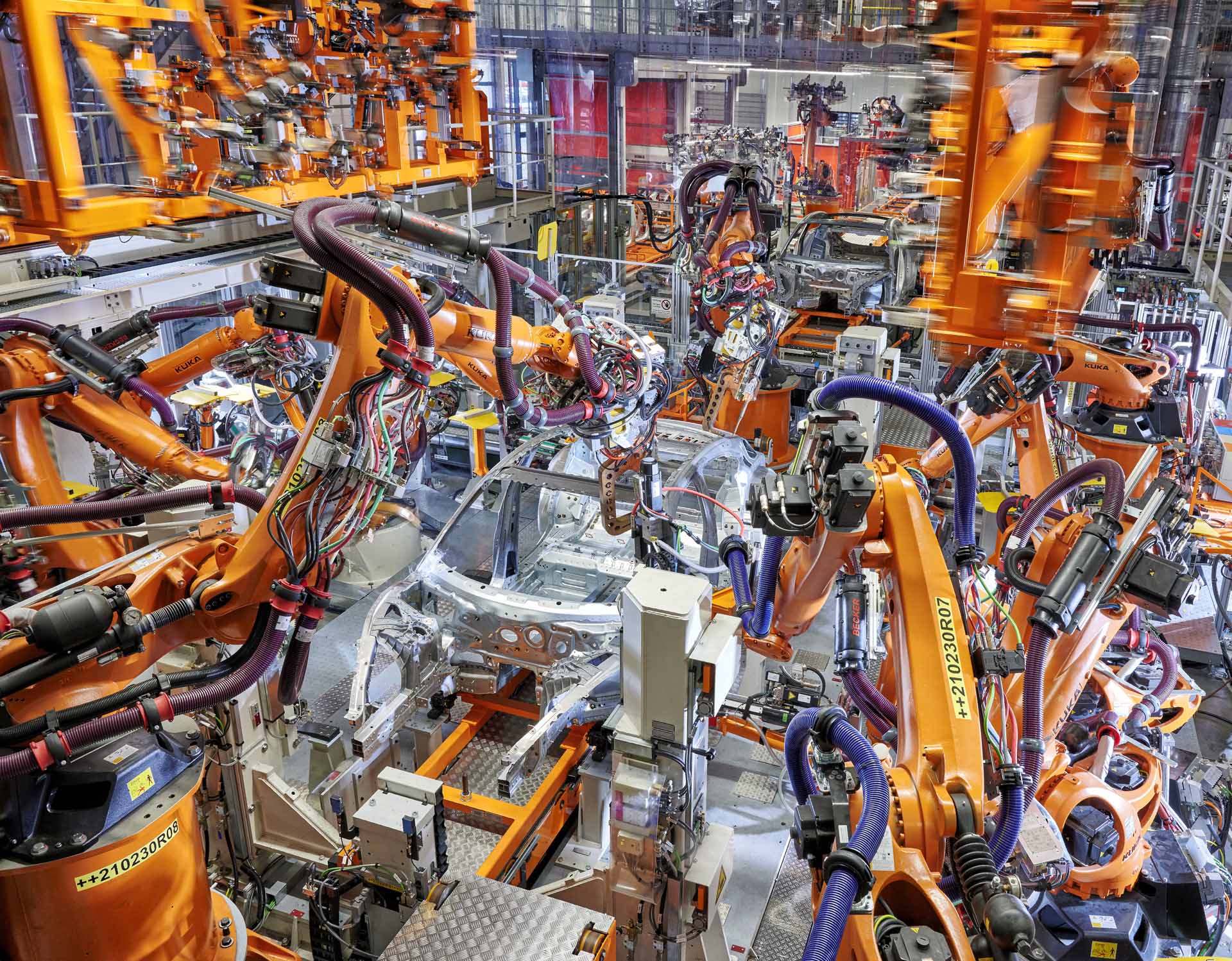

The body shop of the Audi e-tron GT at Böllinger Höfe: The two-way framer combines all manufacturing steps for joining the sides in single system. The system comprises 10 robots and 32 tools.

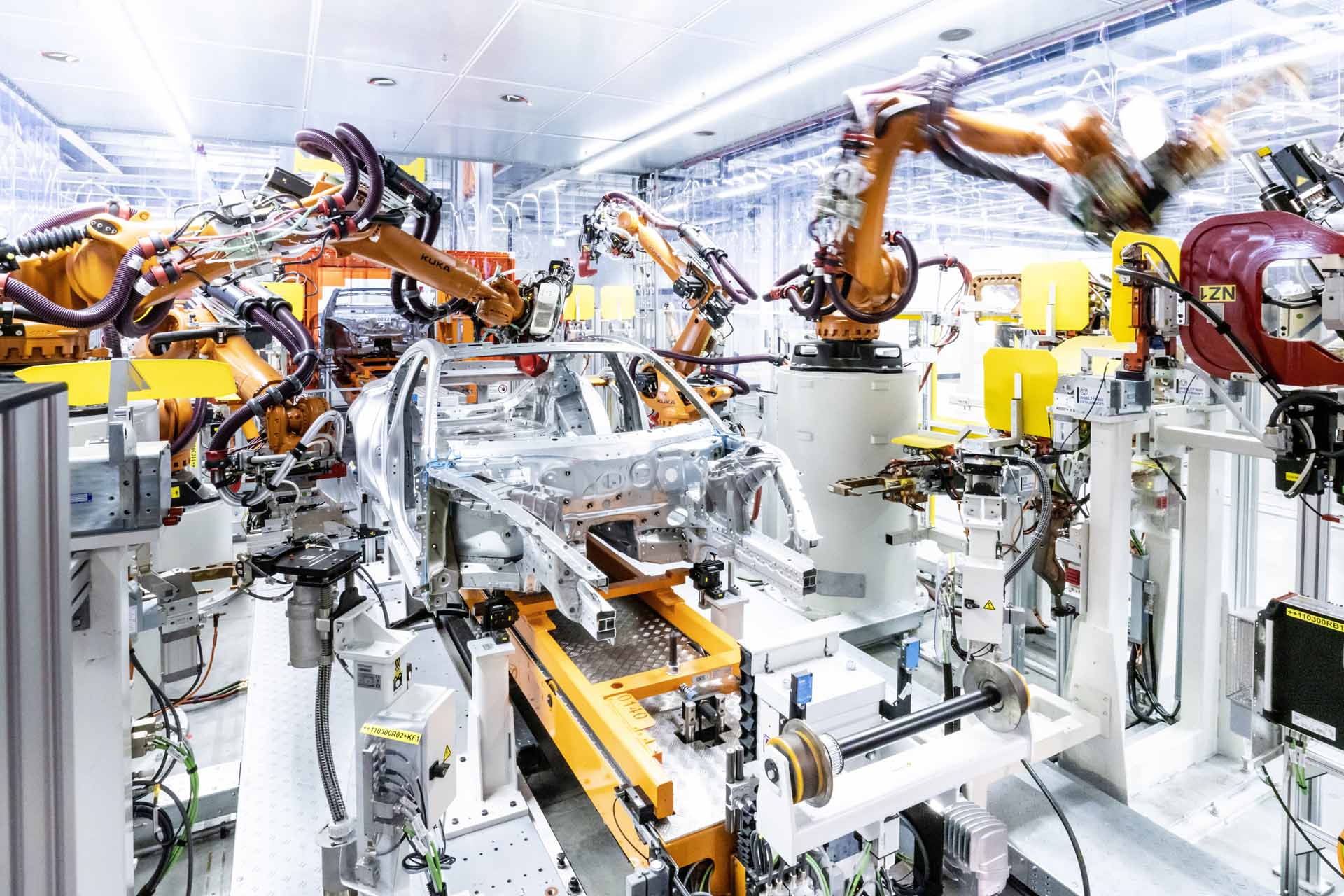

The body shop of the Audi e-tron GT at Böllinger Höfe.

The body shop of the Audi e-tron GT at Böllinger Höfe.

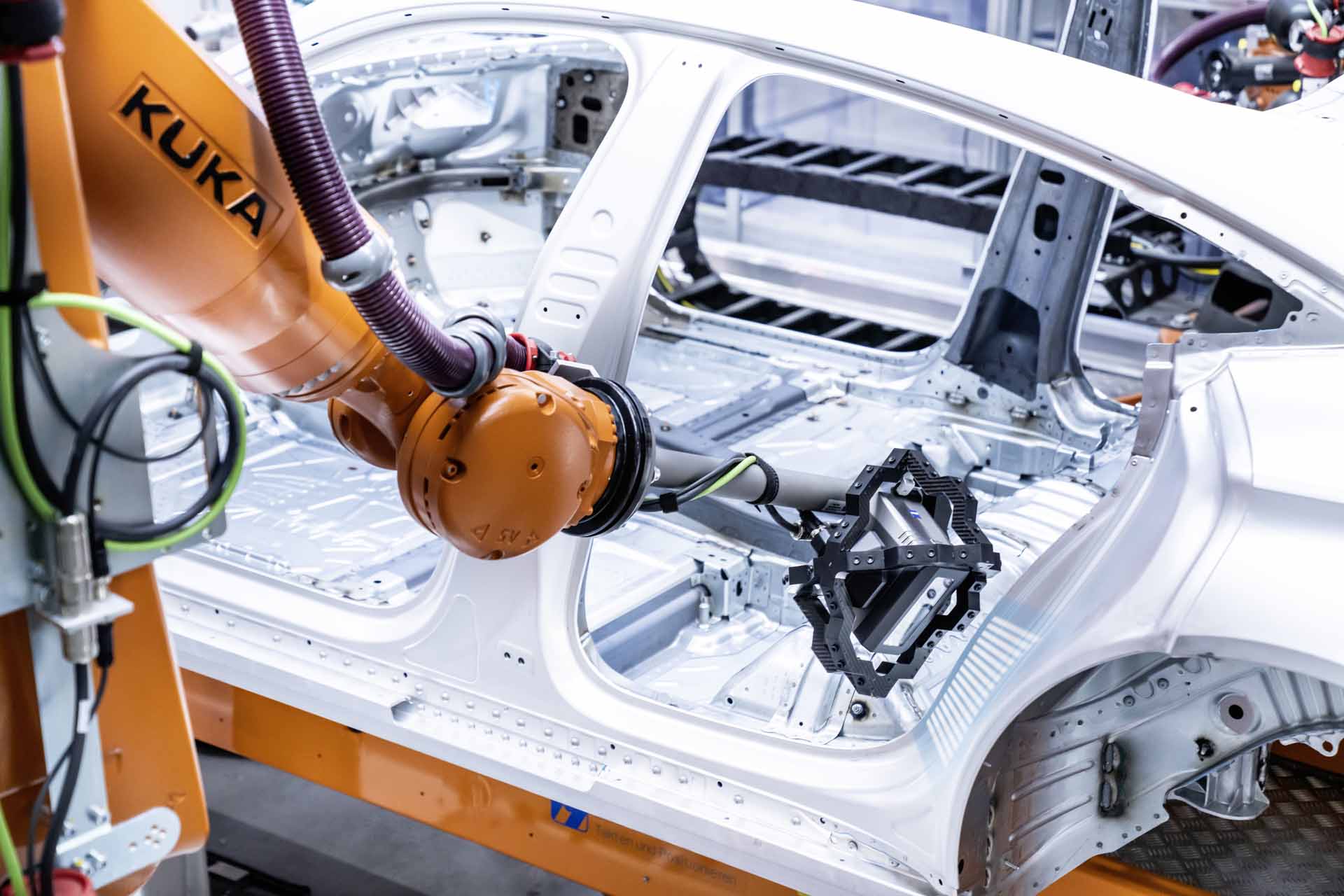

The body shop of the Audi e-tron GT at Böllinger Höfe: The technology of the correlation-free inline measuring works with the highest level of precision.

The body shop of the Audi e-tron GT at Böllinger Höfe.

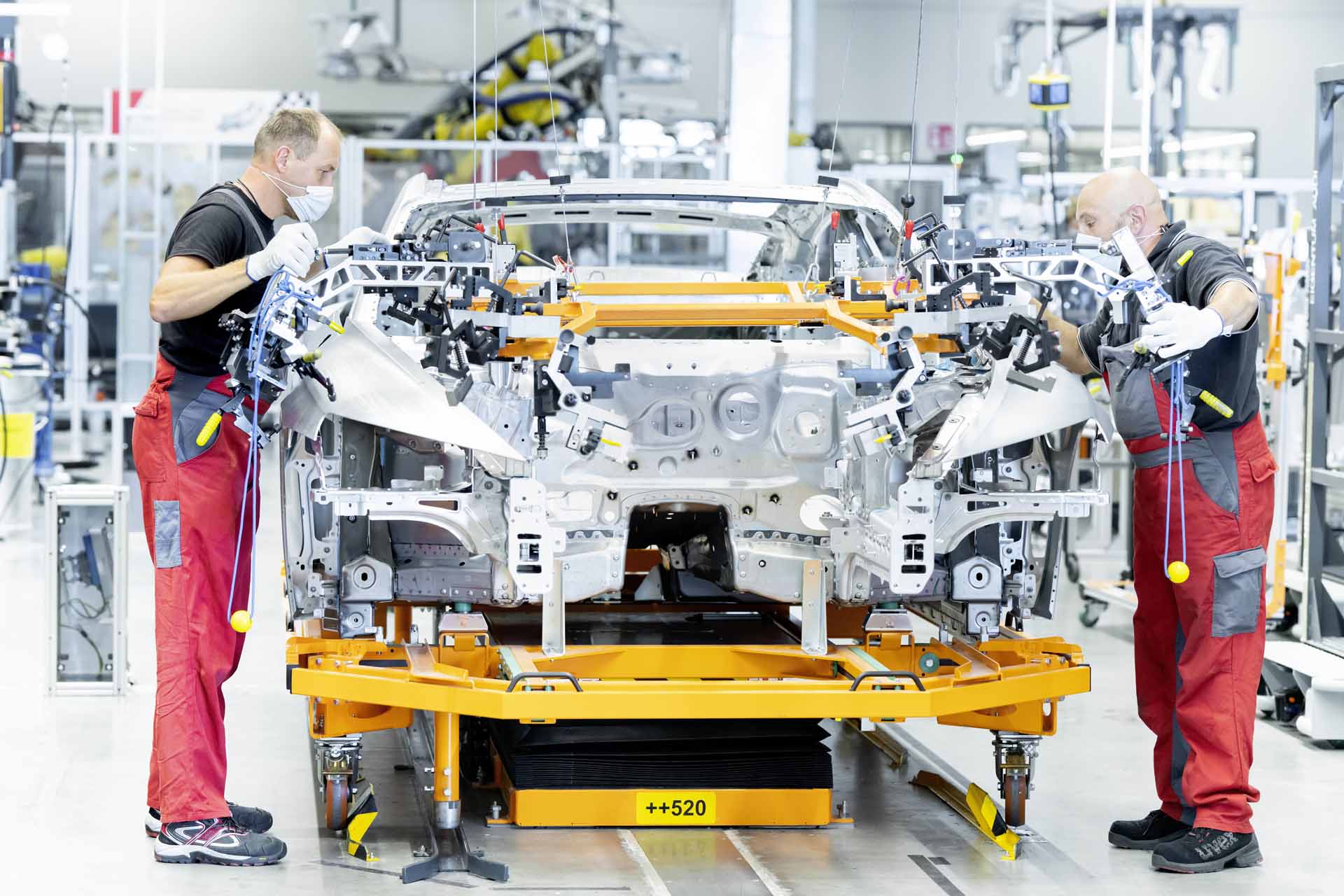

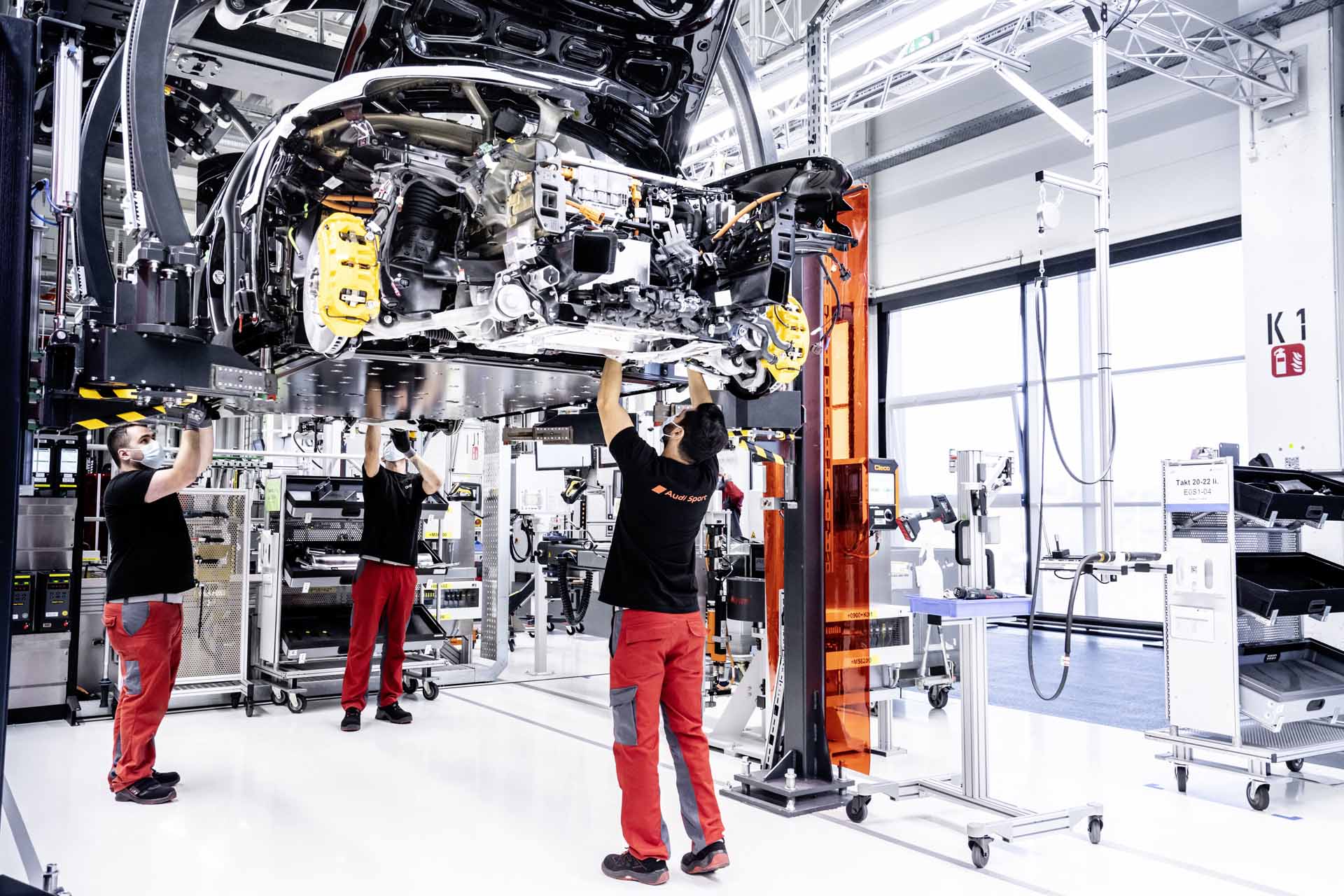

The body shop of the Audi e-tron GT at Böllinger Höfe: The production includes a lot of work done by hand.

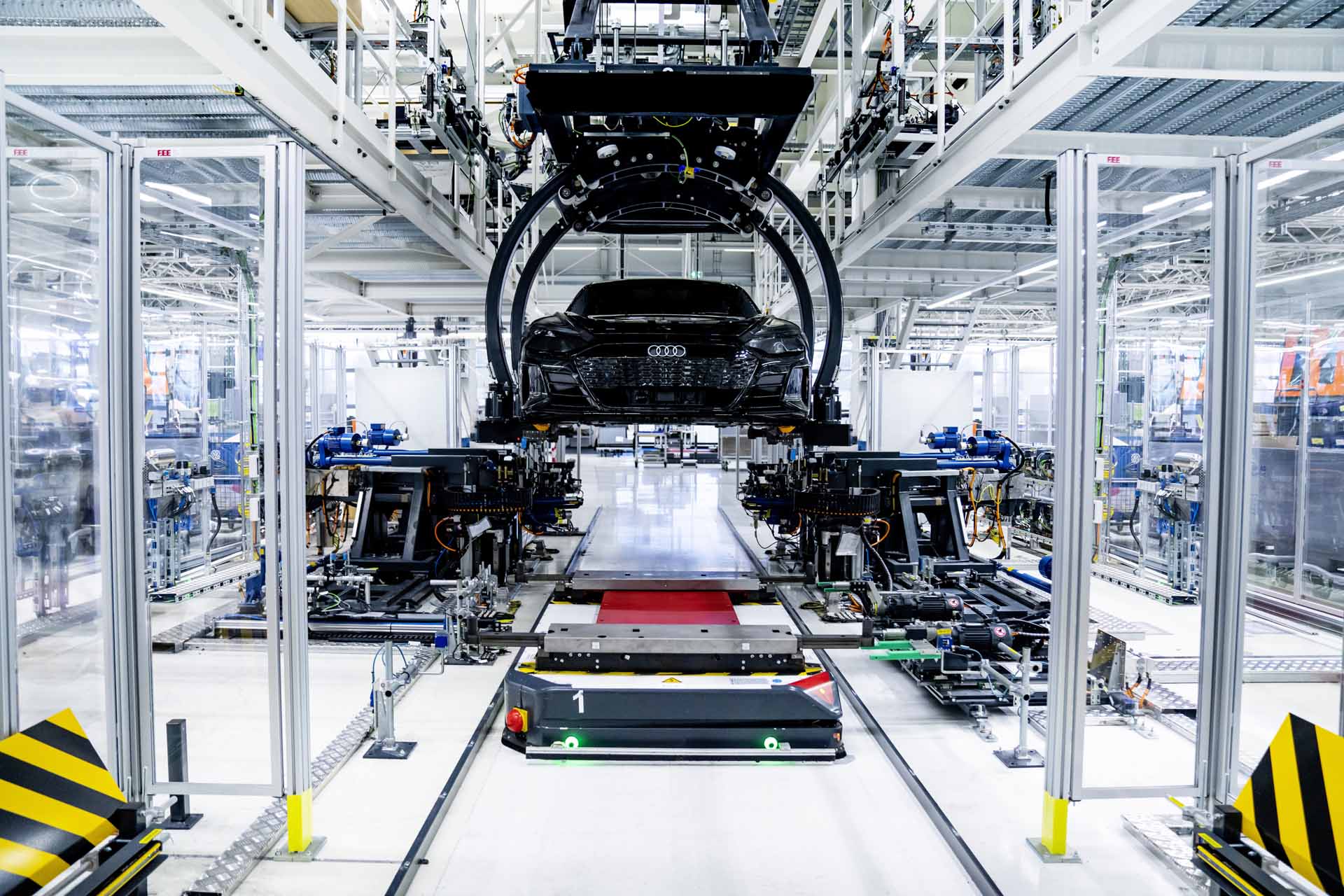

The assembly facility of the Audi e-tron GT at Böllinger Höfe.

The assembly facility of the Audi e-tron GT at Böllinger Höfe.

The assembly facility of the Audi e-tron GT at Böllinger Höfe.

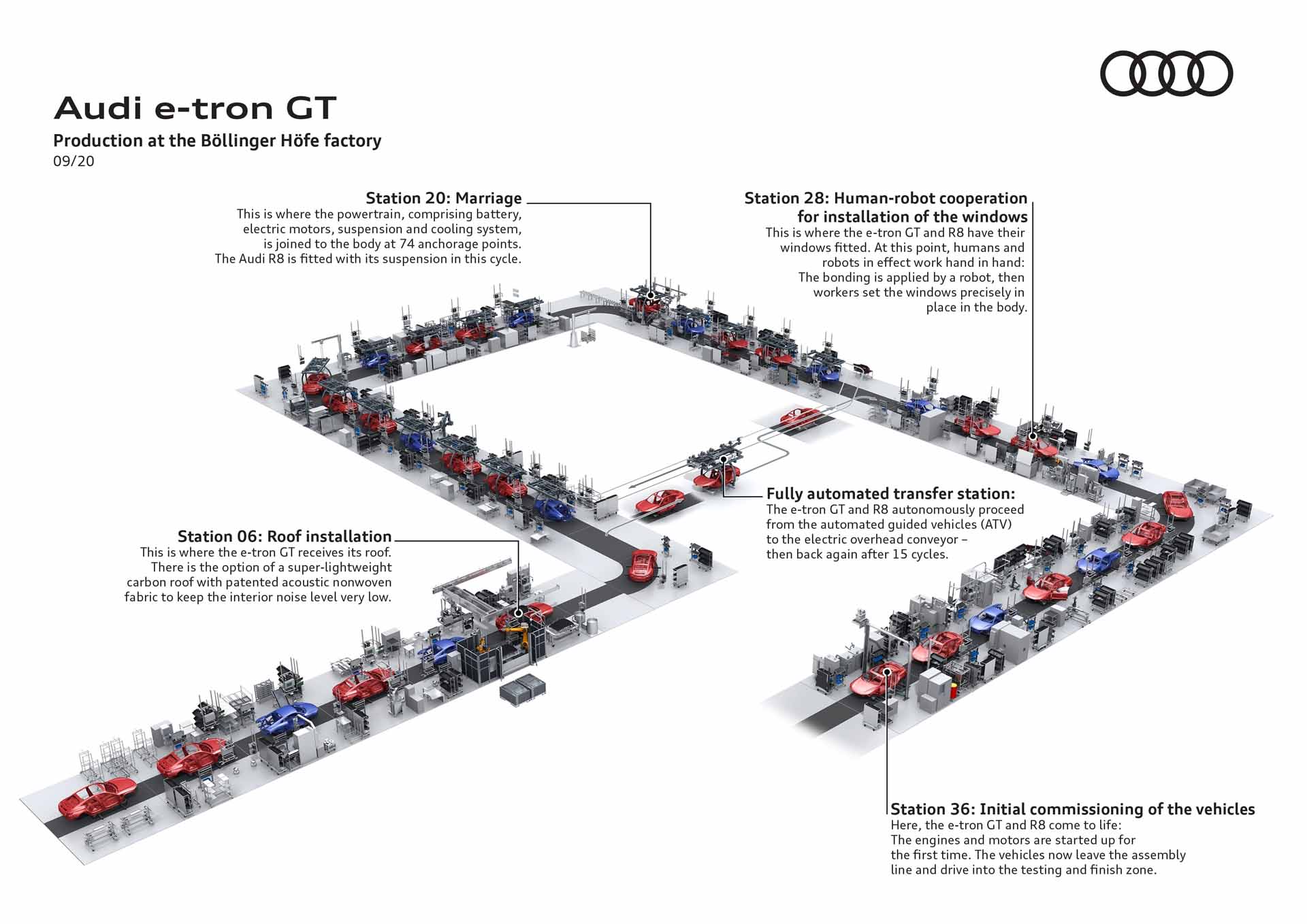

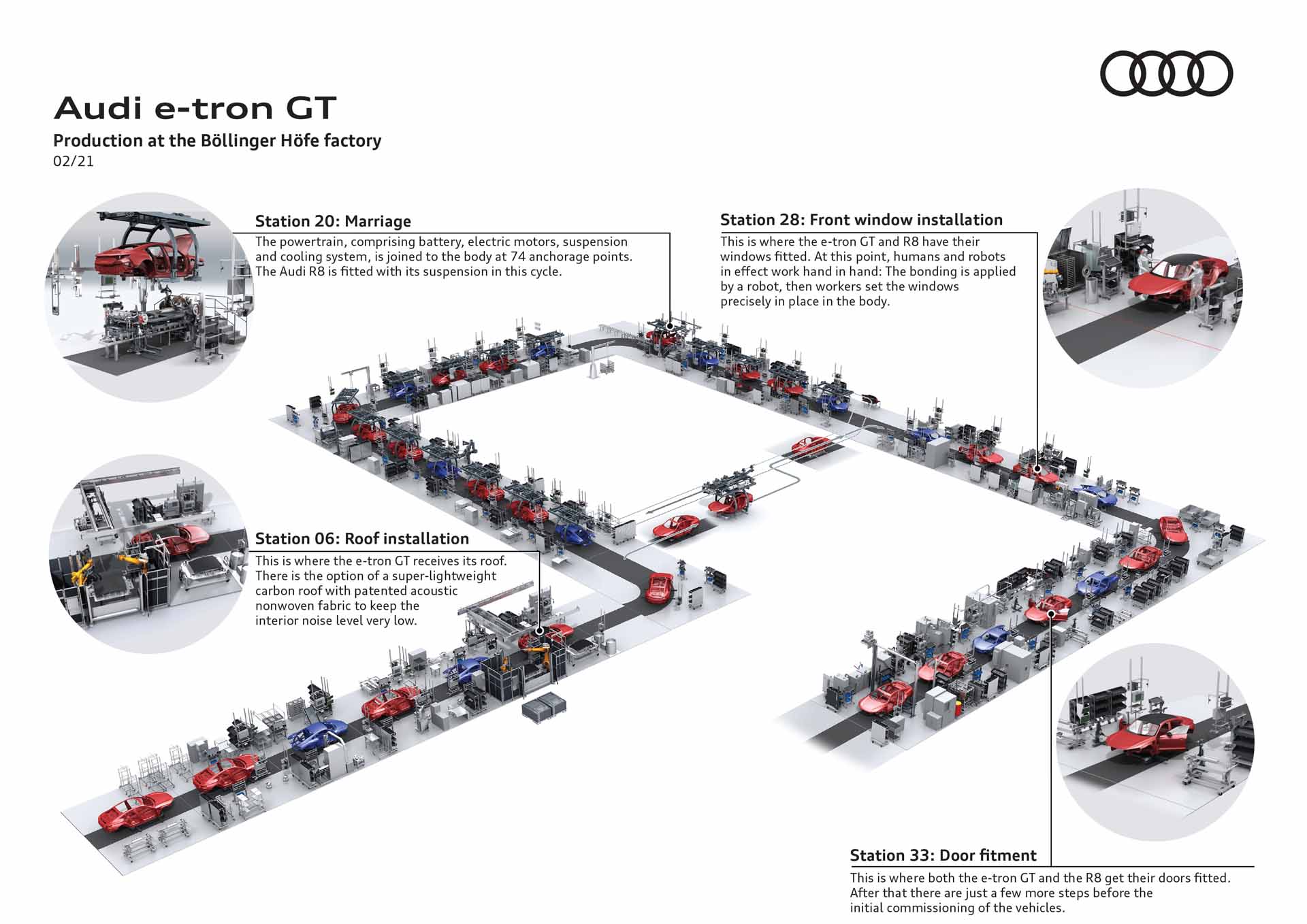

The assembly facility of the Audi e-tron GT at Böllinger Höfe: This is where the e-tron GT receives its optional carbon roof.

The assembly facility of the Audi e-tron GT at Böllinger Höfe: During the marriage, employees fasten the battery and the drive components to the body with screws at 74 points.

The assembly facility of the Audi e-tron GT at Böllinger Höfe.

The assembly facility of the Audi e-tron GT at Böllinger Höfe.

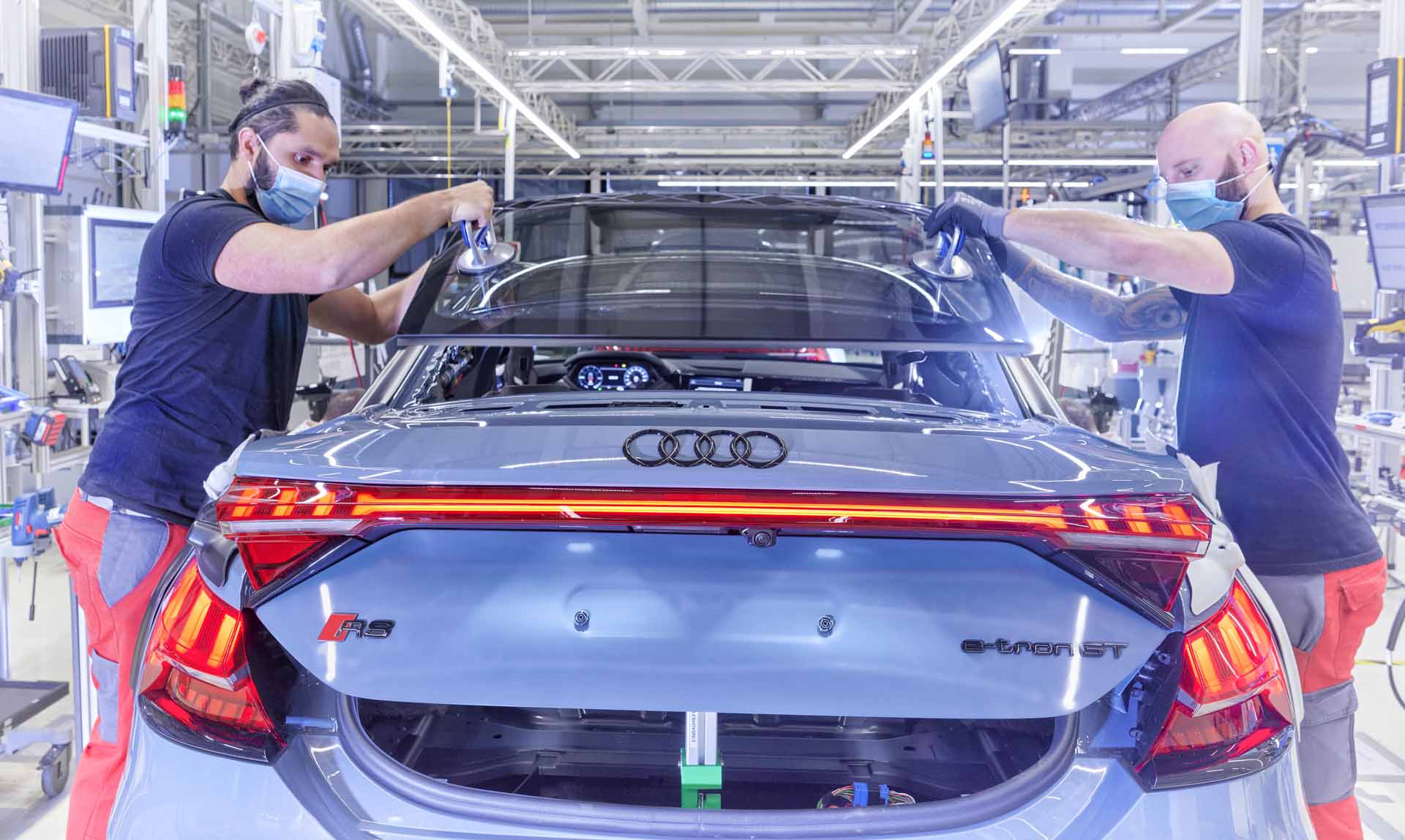

The assembly facility of the Audi e-tron GT at Böllinger Höfe.

The assembly facility of the Audi e-tron GT at Böllinger Höfe.

The assembly facility of the Audi e-tron GT at Böllinger Höfe: During the marriage, employees fasten the battery and the drive components to the body with screws at 74 points.

The Audi e-tron GT in the test center at Böllinger Höfe.

Audi tests assembly processes for the e-tron GT entirely virtually.

The Audi e-tron GT in the finishing area at Böllinger Höfe.

The body shop of the Audi e-tron GT at Böllinger Höfe: The production includes a lot of precision.

The body shop of the Audi e-tron GT at Böllinger Höfe.

Manual work in the body shop of the Audi e-tron GT

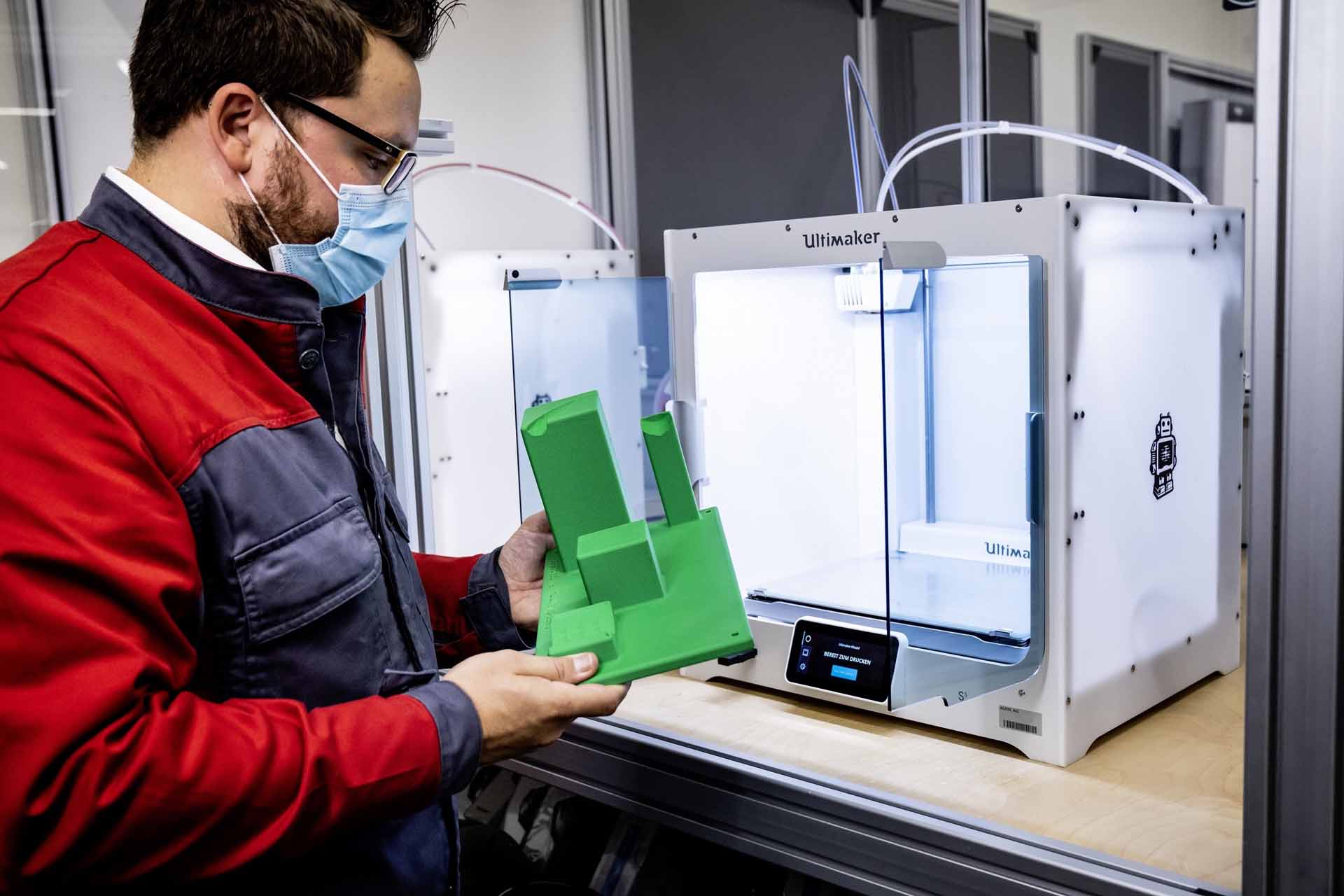

Plastic 3D printing at the Audi Böllinger Höfe

Body shop: With an extreme drawing depth, the aluminum side panel frame provides the distinctive quattro blisters of the Audi e-tron GT.

The perfect quality of every Audi e-tron GT is checked in the assembly finishing area.

Using special software and hardware, production halls and entire buildings at the Audi site in Neckarsulm were scanned in three dimensions.

Using parts from the 3D printer, individual elements can also be physically tested in virtual space in the future.

When planning the assembly of the e-tron GT, all assembly processes such as workflows and actions by employees were tested and optimized in virtual rooms.

The assembly facility of the Audi e-tron GT at Böllinger Höfe.

The assembly facility of the Audi e-tron GT at Böllinger Höfe.

The assembly facility of the Audi e-tron GT at Böllinger Höfe.

The body shop of the Audi e-tron GT at Böllinger Höfe.

The body shop of the Audi e-tron GT at Böllinger Höfe.

The body shop of the Audi e-tron GT at Böllinger Höfe.

The body shop of the Audi e-tron GT at Böllinger Höfe.

The body shop of the Audi e-tron GT at Böllinger Höfe.

The body shop of the Audi e-tron GT at Böllinger Höfe.

The assembly facility of the Audi e-tron GT at Böllinger Höfe.

The assembly facility of the Audi e-tron GT at Böllinger Höfe.

The assembly facility of the Audi e-tron GT at Böllinger Höfe.

The assembly facility of the Audi e-tron GT at Böllinger Höfe.

The assembly facility of the Audi e-tron GT at Böllinger Höfe.

The assembly facility of the Audi e-tron GT at Böllinger Höfe.

The assembly facility of the Audi e-tron GT at Böllinger Höfe.

The assembly facility of the Audi e-tron GT at Böllinger Höfe.

The assembly facility of the Audi e-tron GT at Böllinger Höfe.

The assembly facility of the Audi e-tron GT at Böllinger Höfe.

The assembly facility of the Audi e-tron GT at Böllinger Höfe.

The assembly facility of the Audi e-tron GT at Böllinger Höfe.

The assembly facility of the Audi e-tron GT at Böllinger Höfe.

The assembly facility of the Audi e-tron GT at Böllinger Höfe.

The assembly facility of the Audi e-tron GT at Böllinger Höfe.

Production at the Böllinger Höfe factory

Technique

Audi e-tron GT quattro

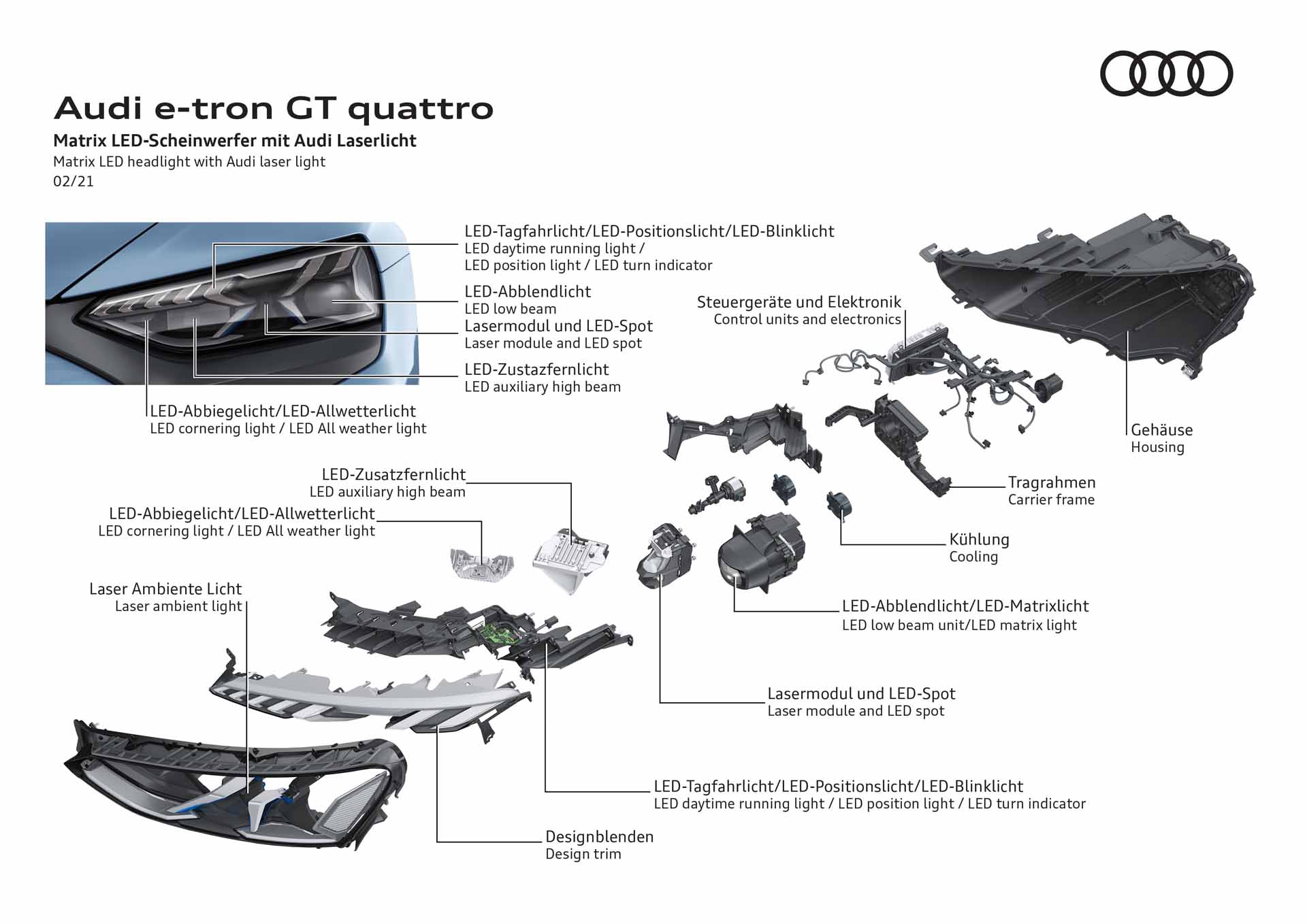

Matrix LED headlight with Audi laser light

Daytime running lights

Rear light signature

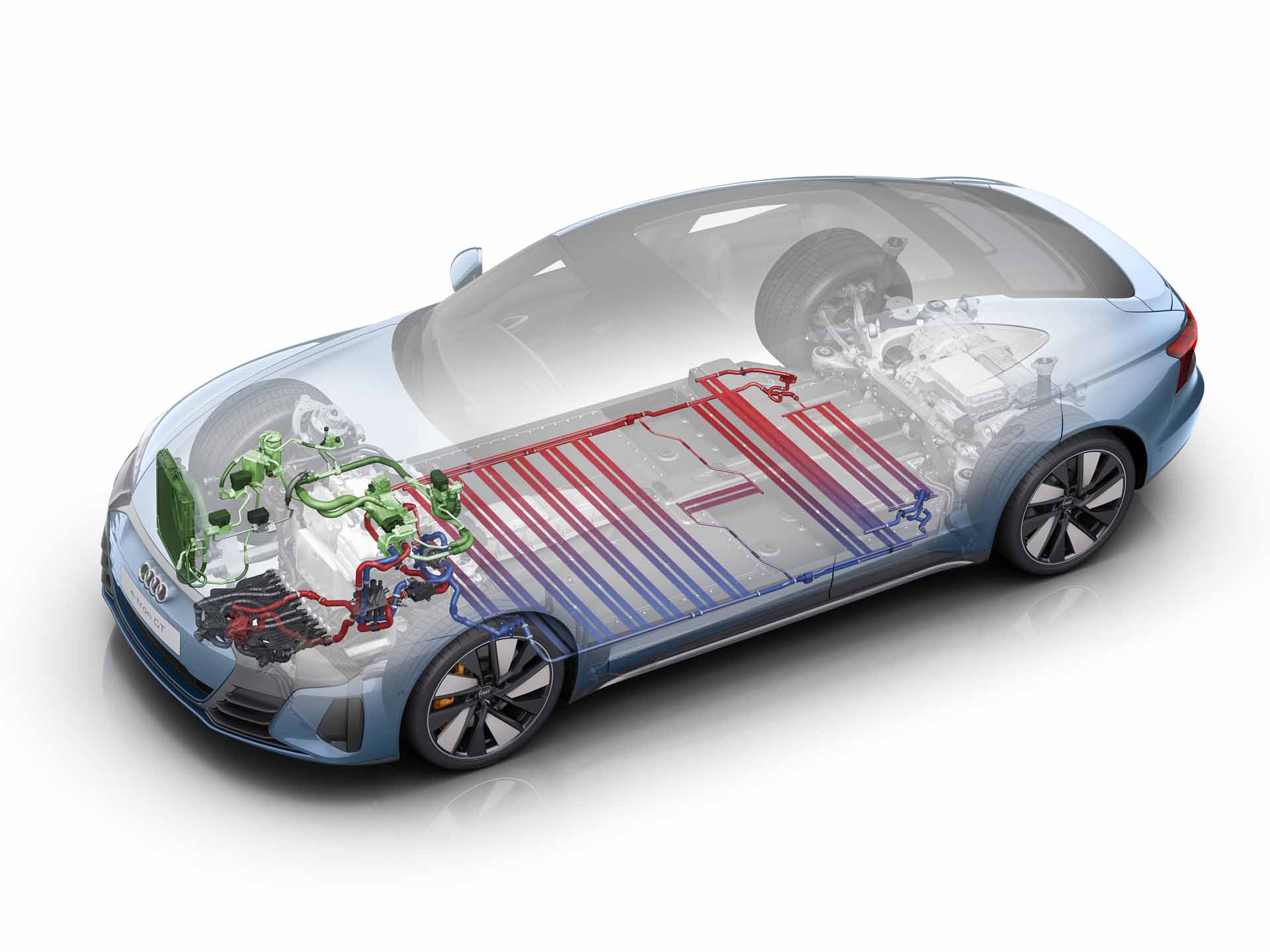

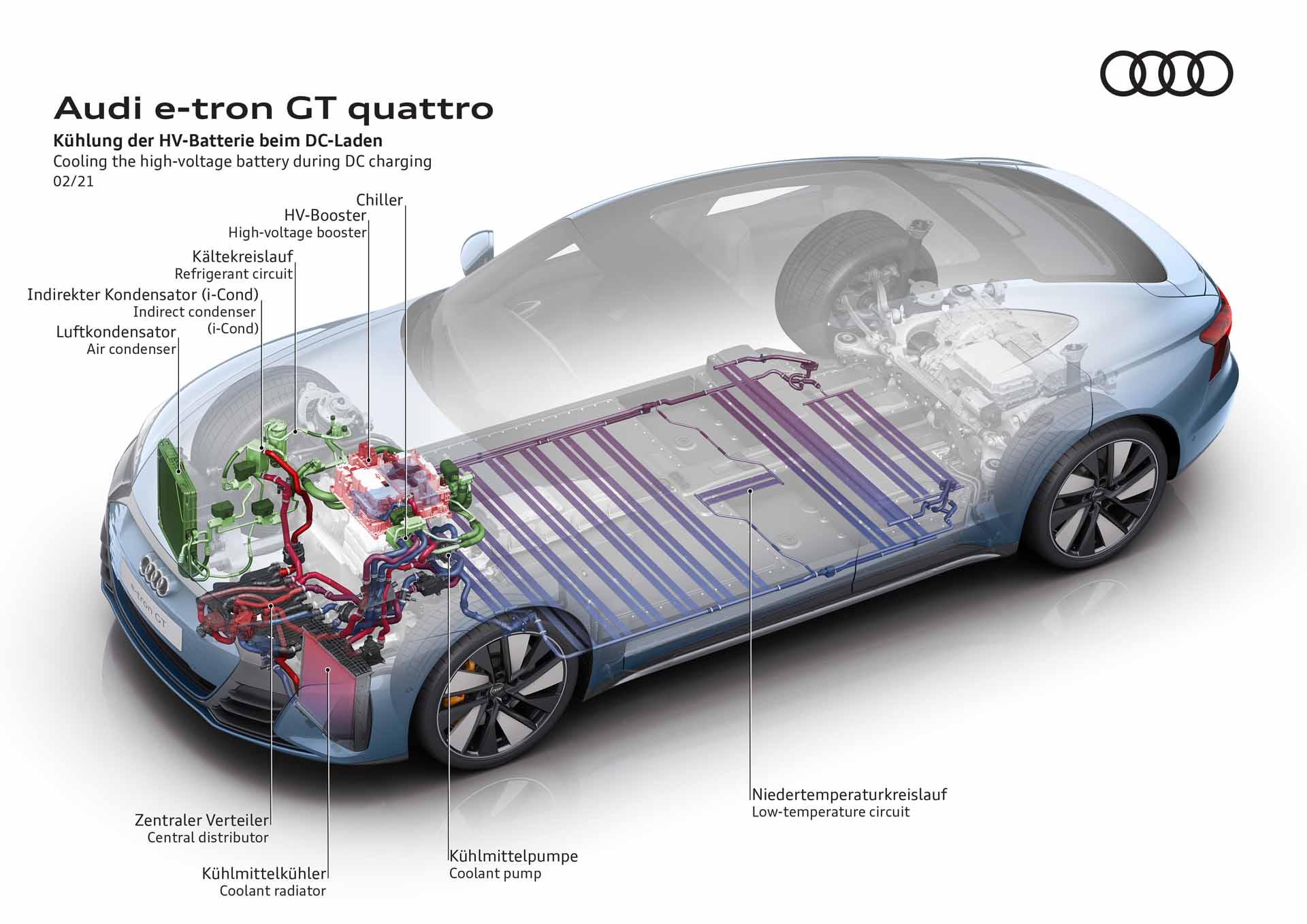

Cooling the high-voltage battery during DC charging

Refrigerant circuit

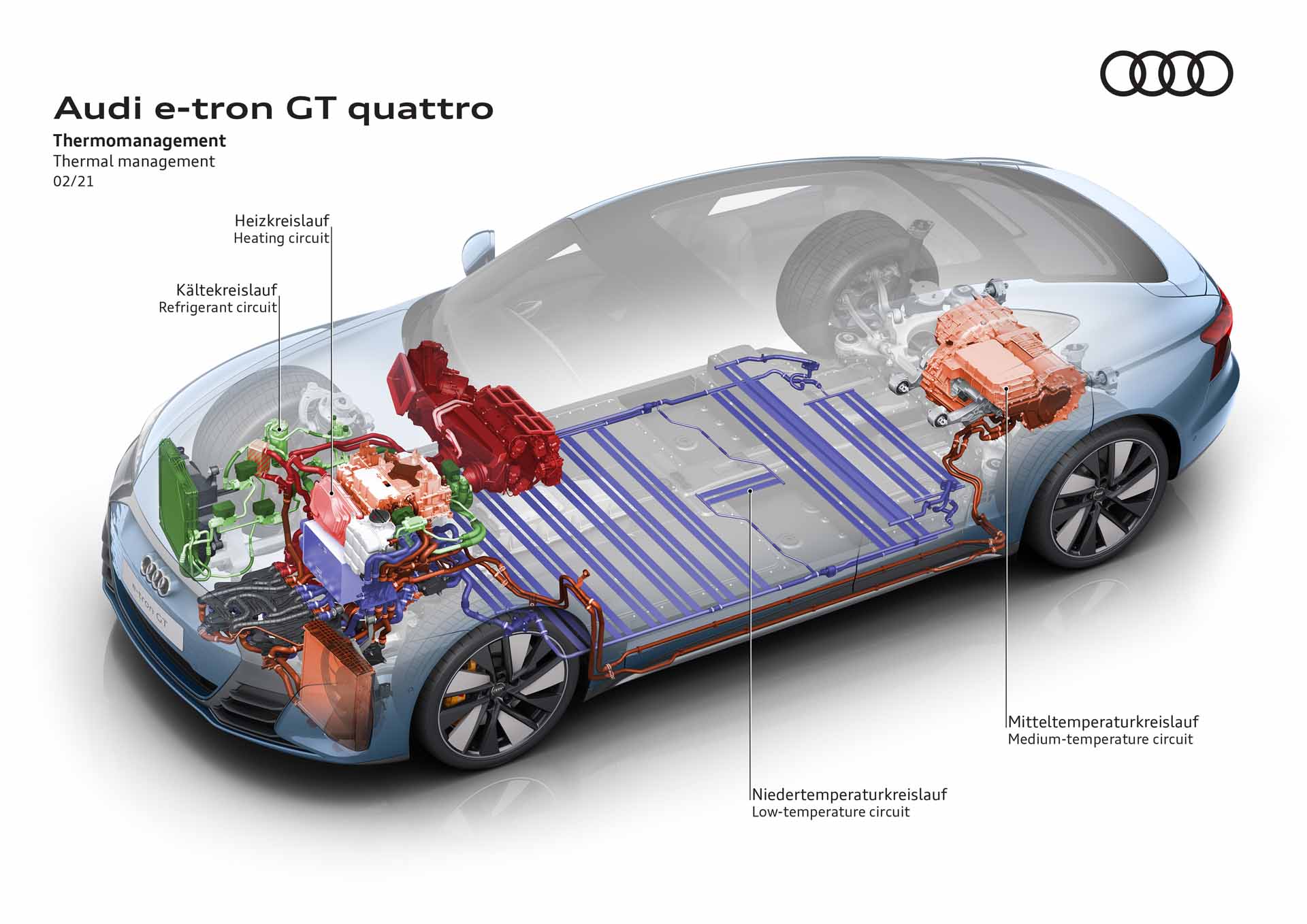

Thermal management

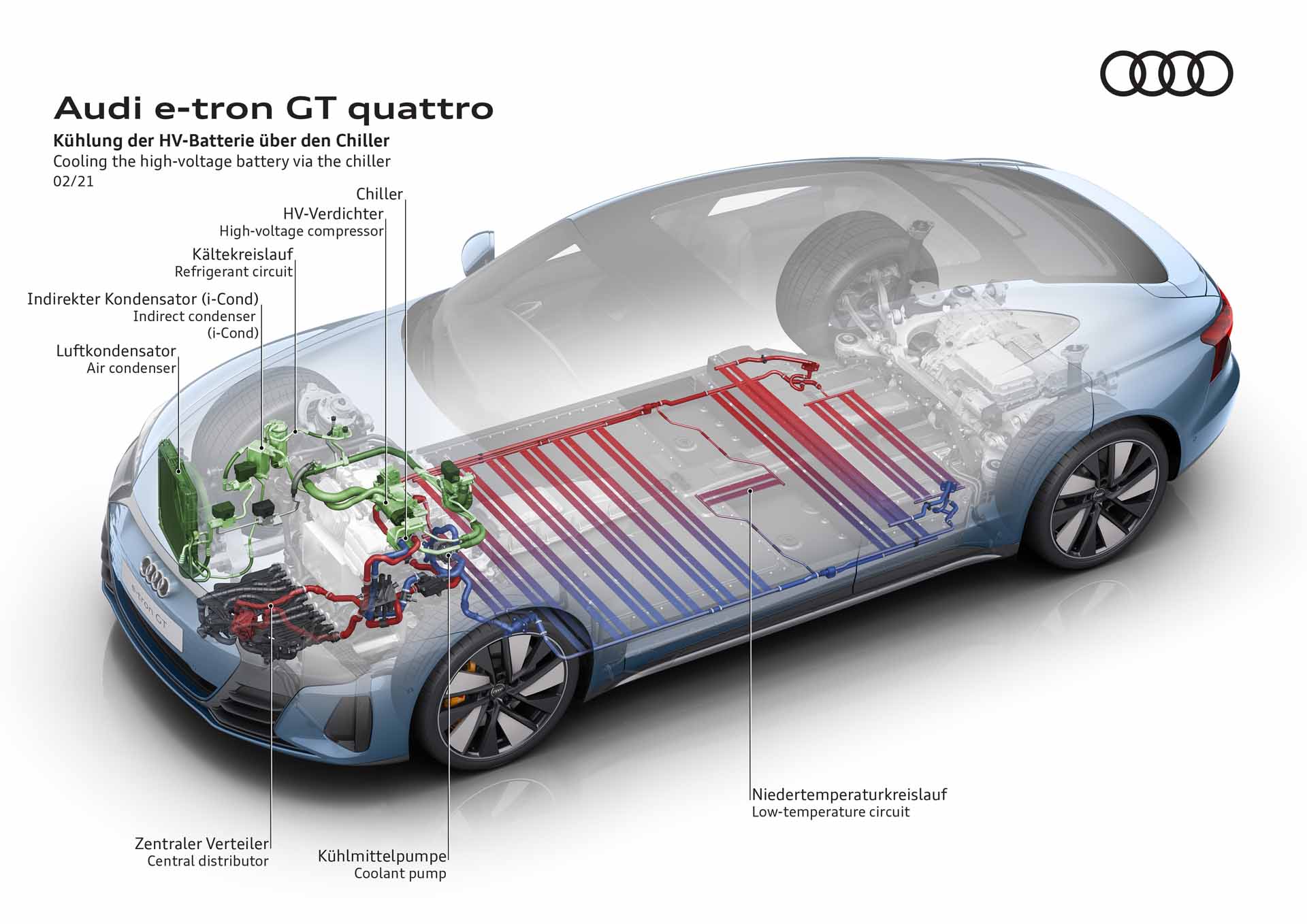

Cooling the high-volatge battery via the chiller

Cooling the electric motors

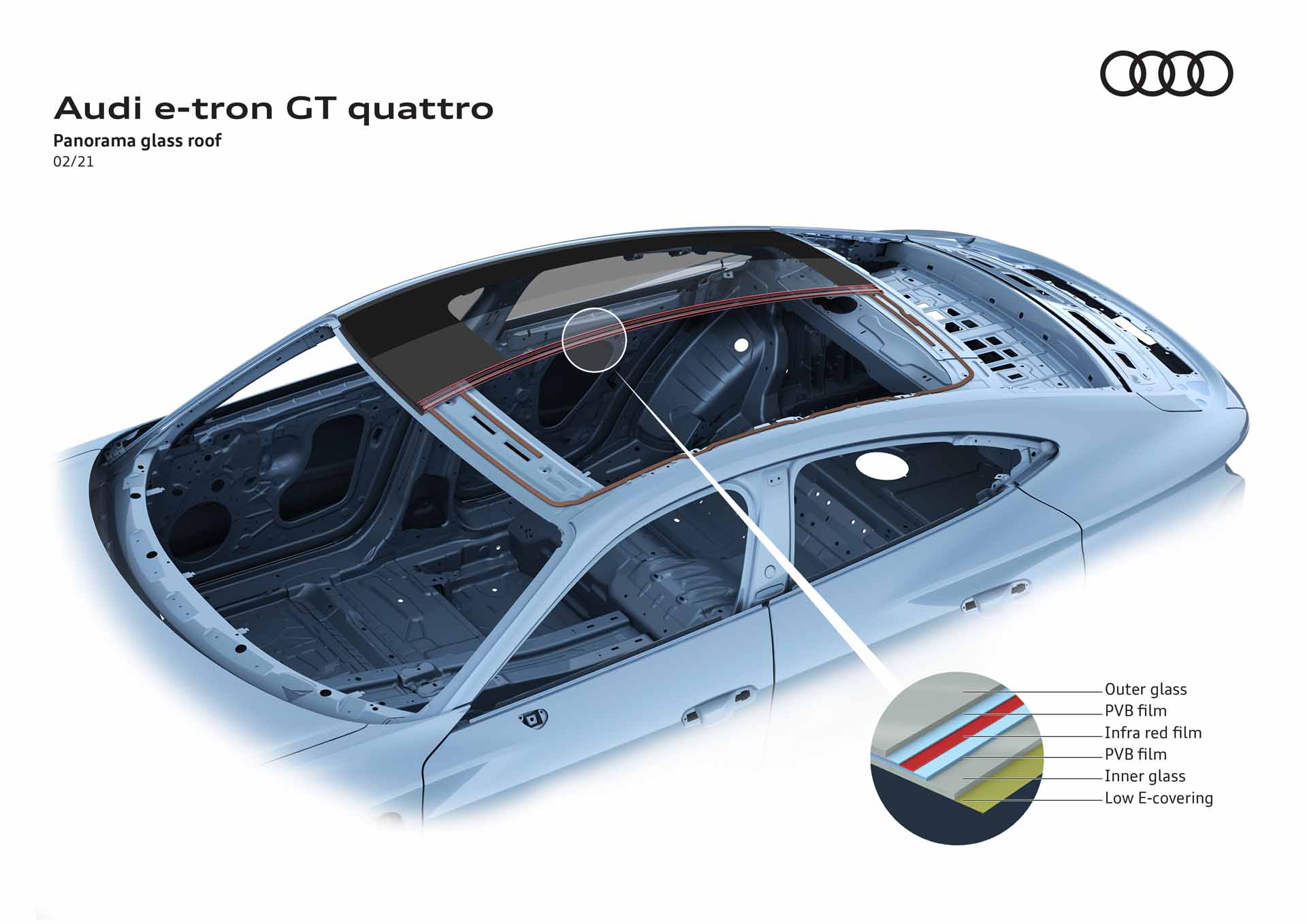

Panorama glass roof

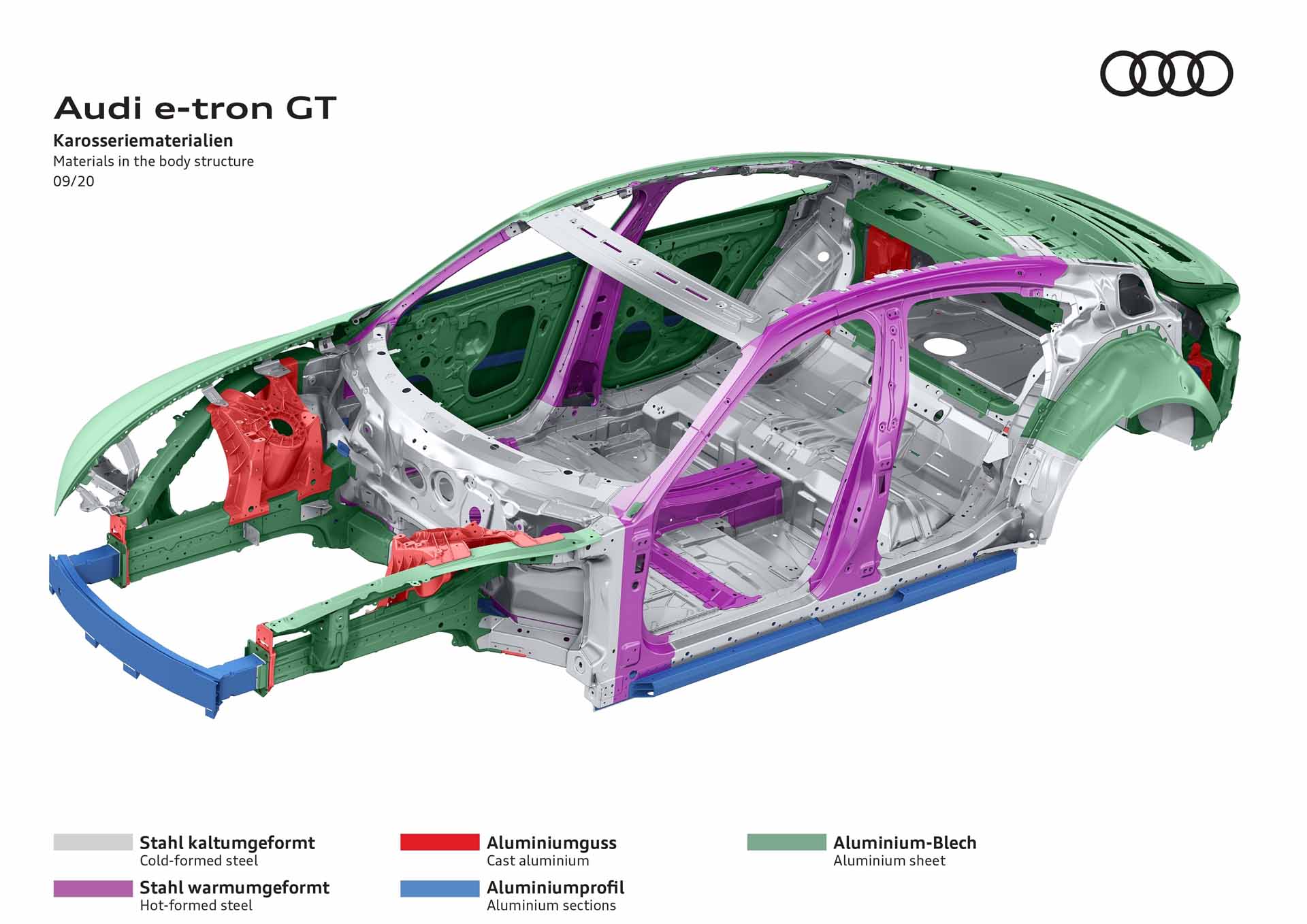

Load paths in the body structure

Integration of the Hochvolt-battery in the body structure

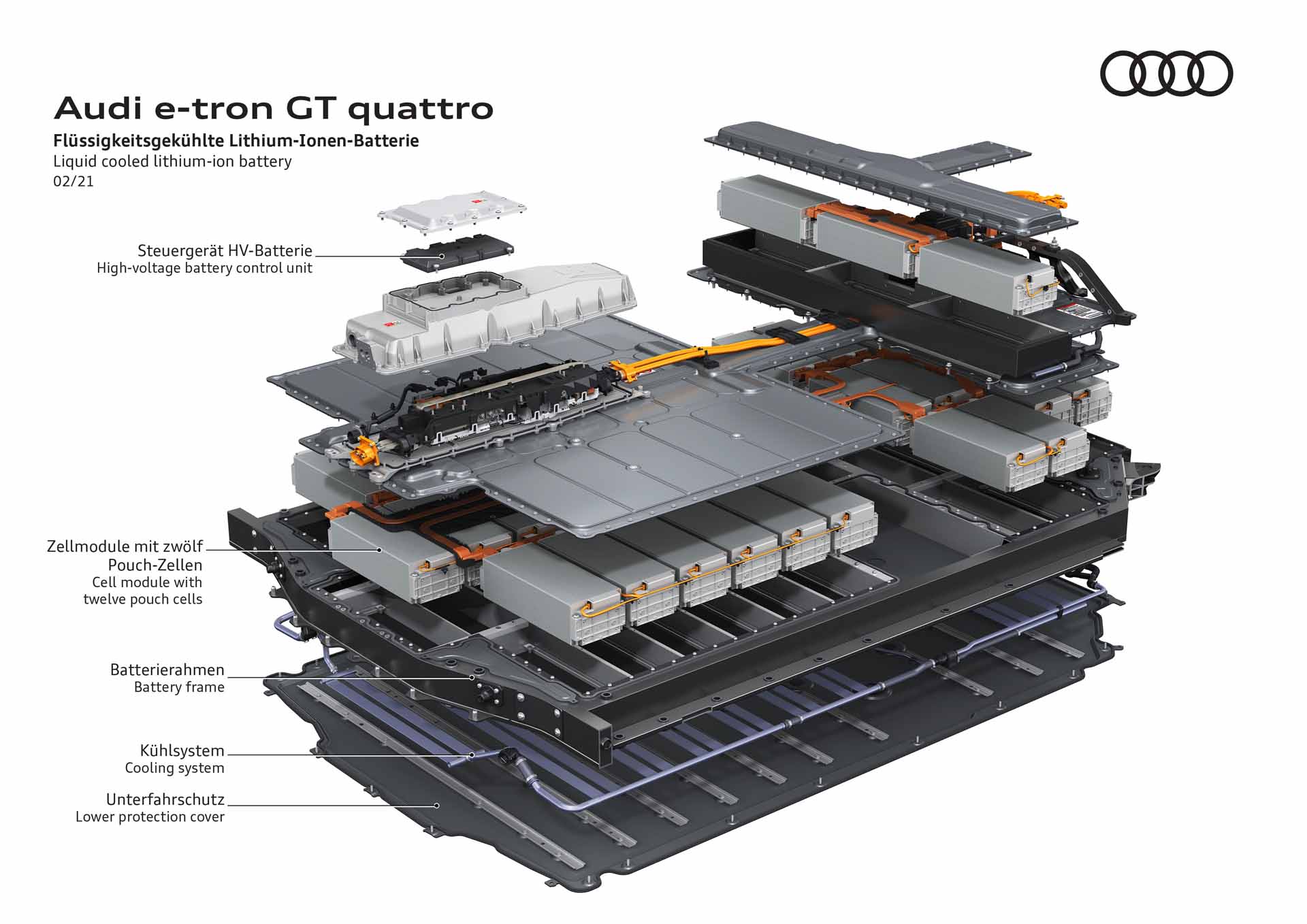

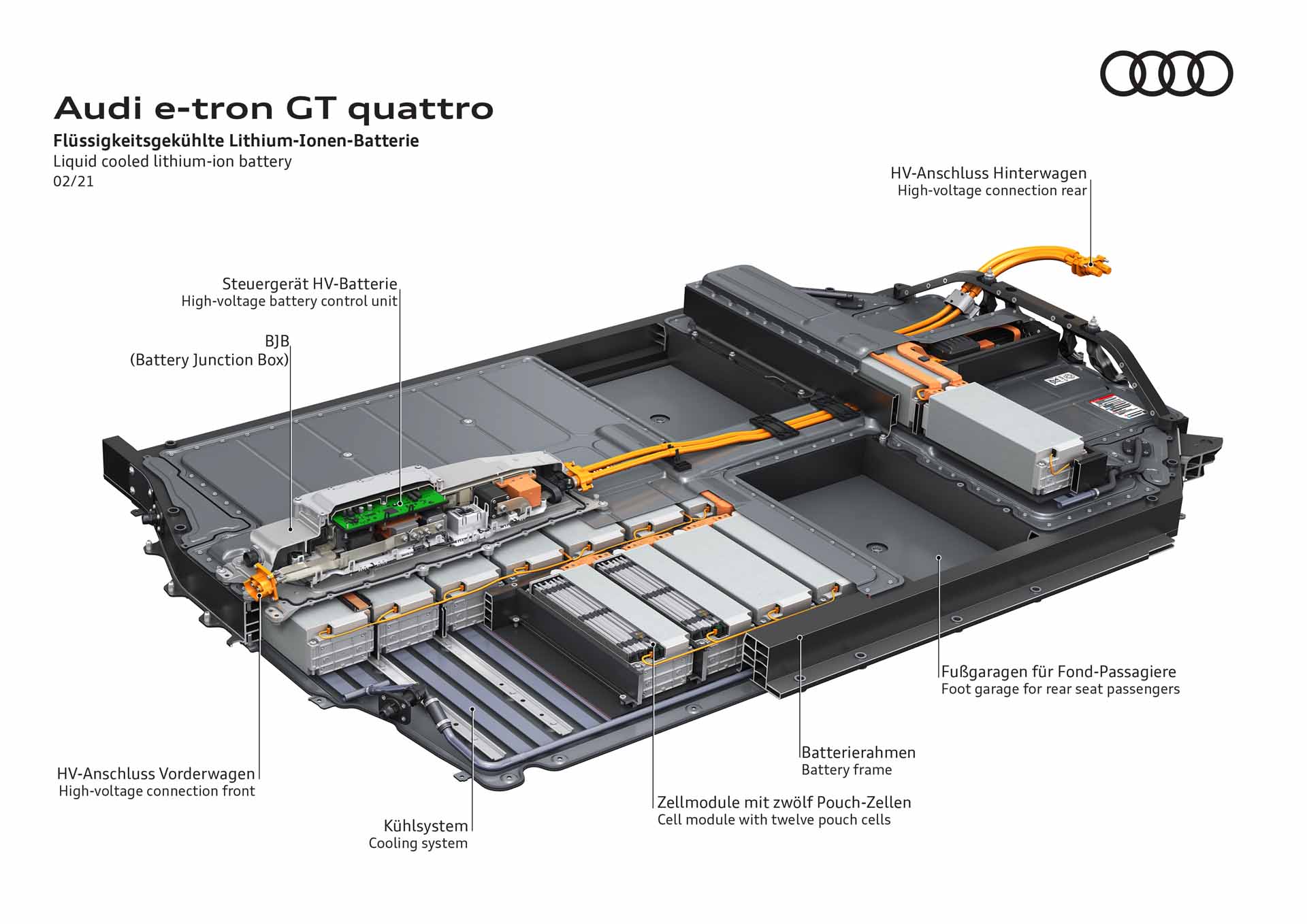

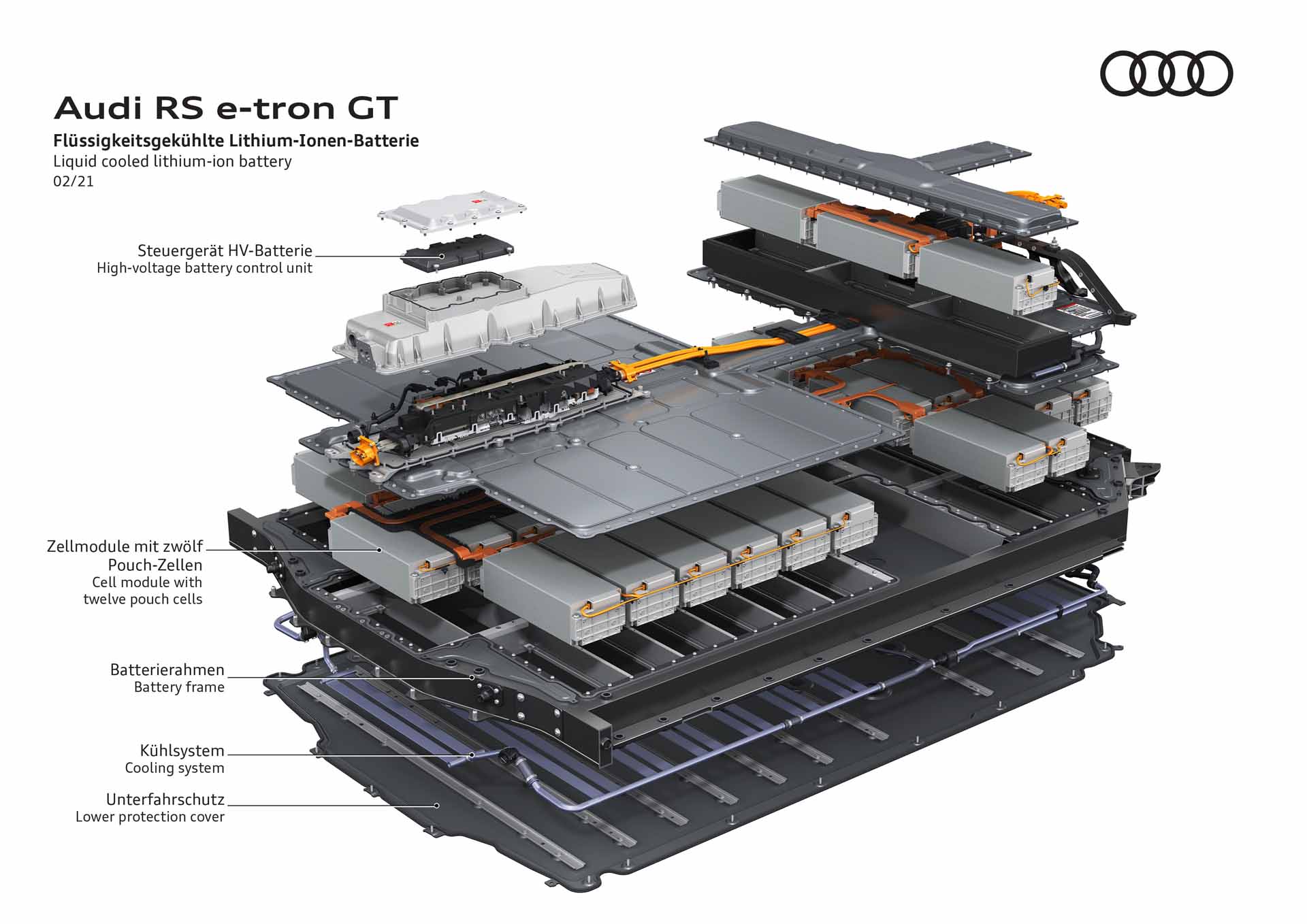

Liquid cooled lithium-ion battery

Drivetrain with 800-volt system voltage

Suspension and drivetrain

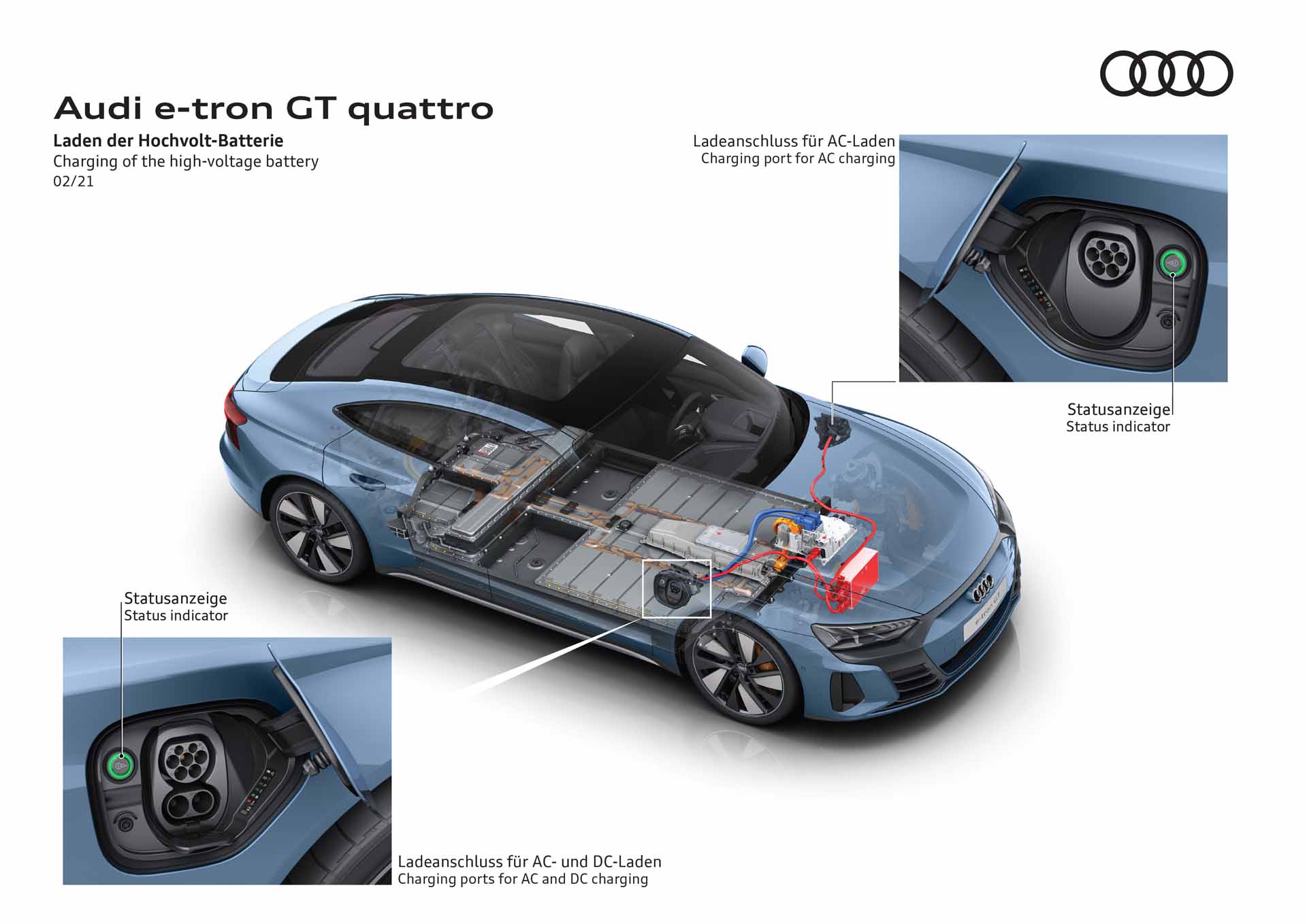

Charging of the high-voltage battery

Charging of the high-voltage battery

Liquid cooled lithium-ion battery

Luggage compartment (frunk and trunk)

Sensor areas for environment observation

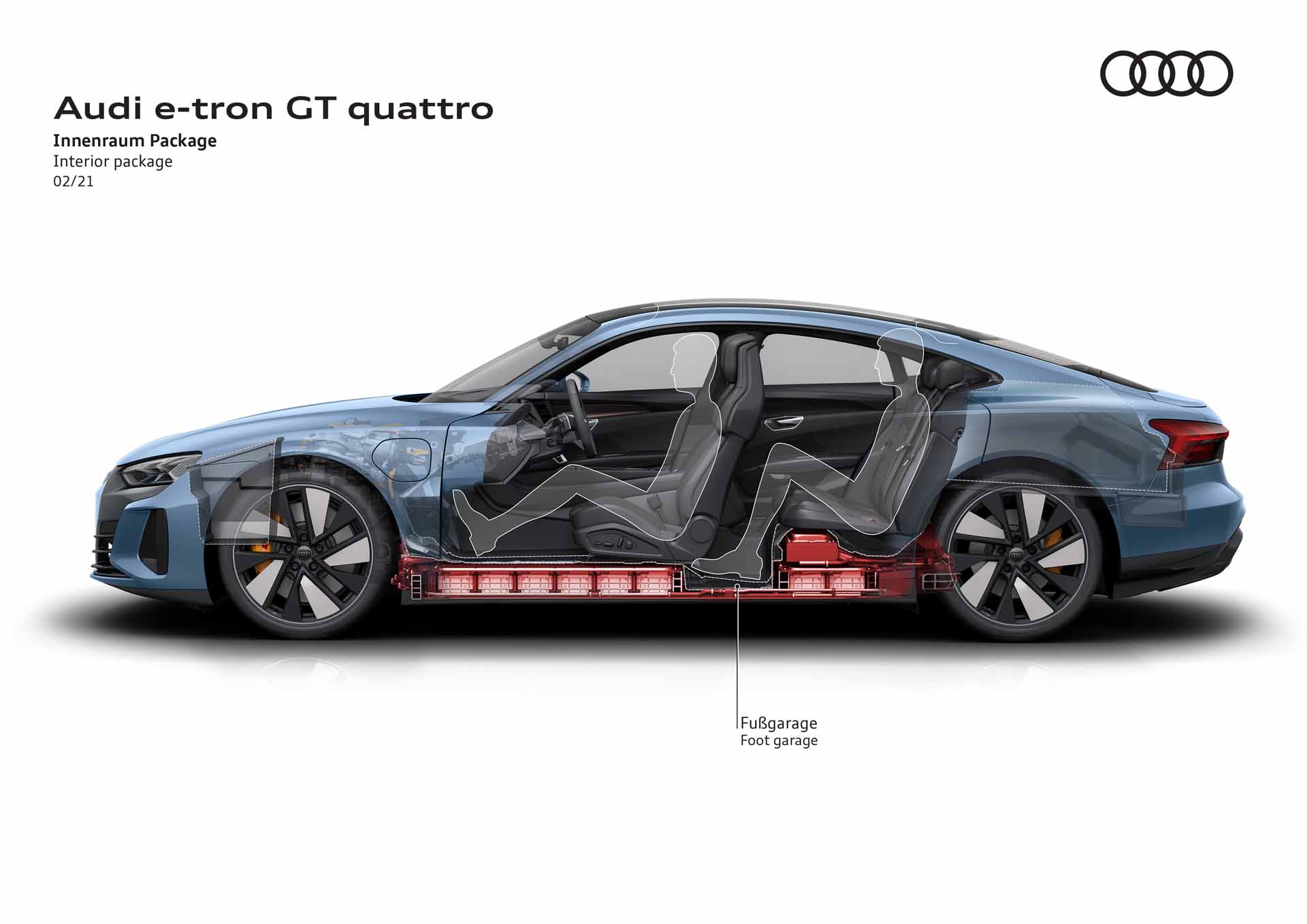

Interior package

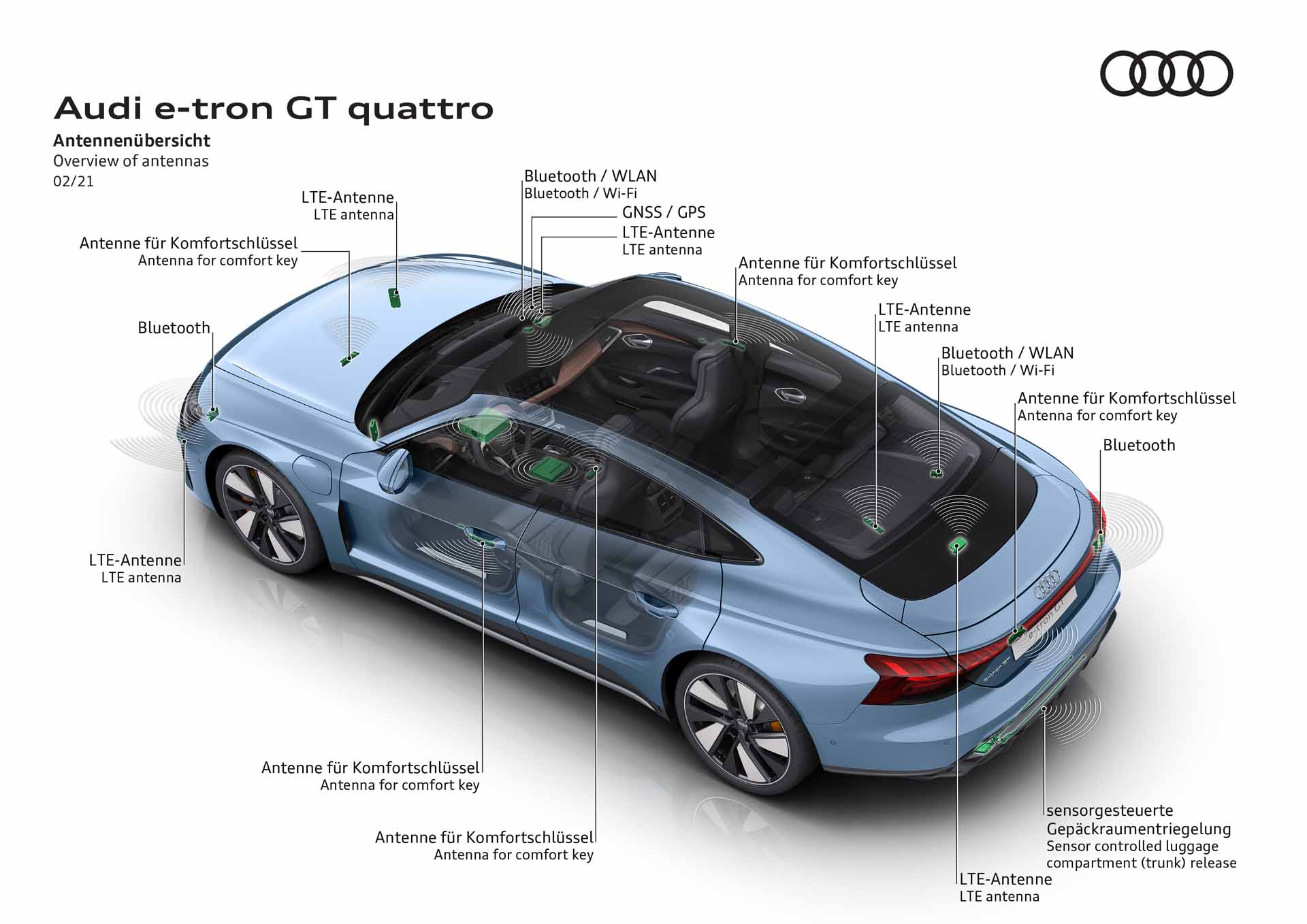

Overview of antennas

Passive safety

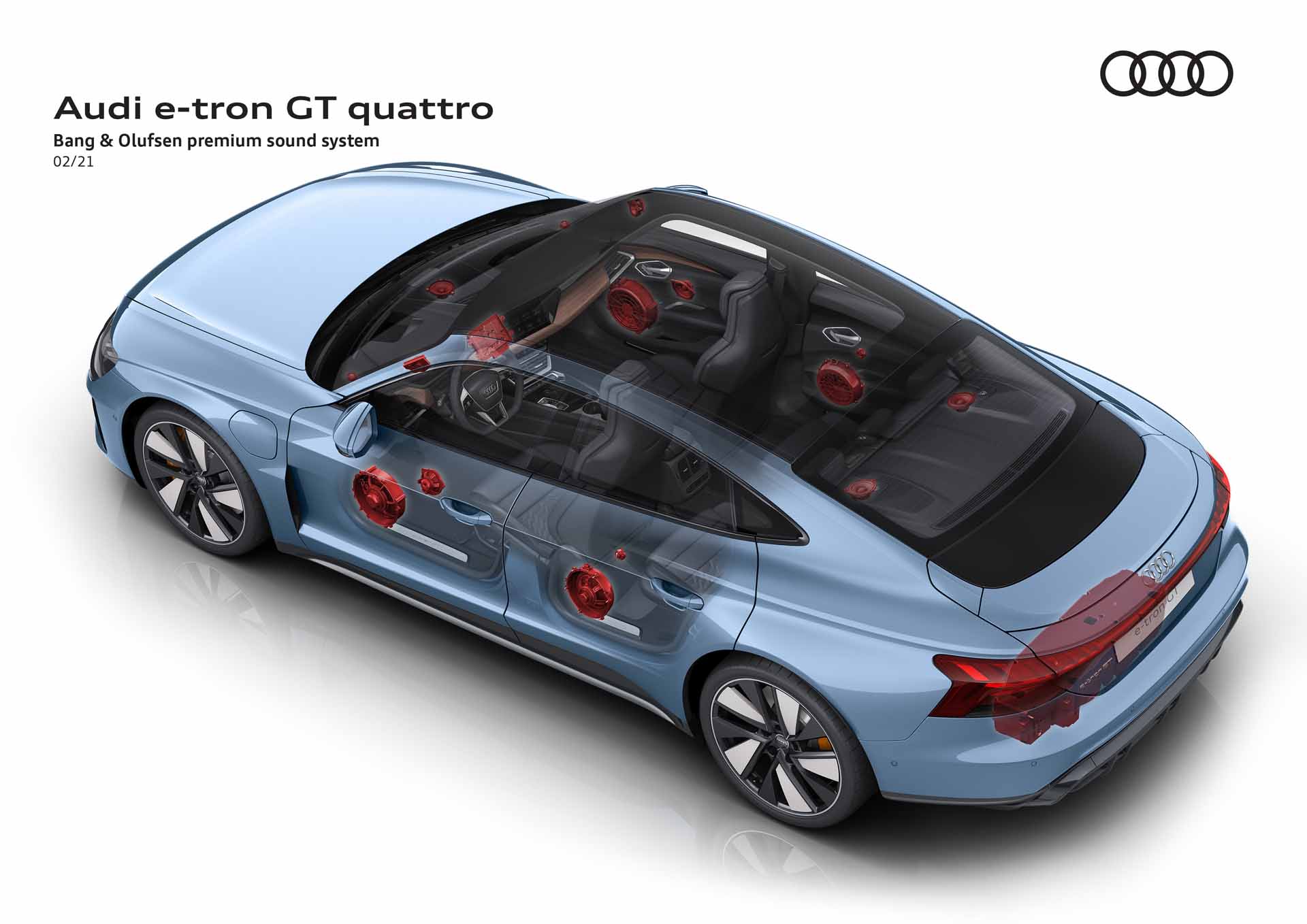

Bang & Olufsen premium sound system

Audi e-tron GT quattro

Interior

Interior

Leather-free interior

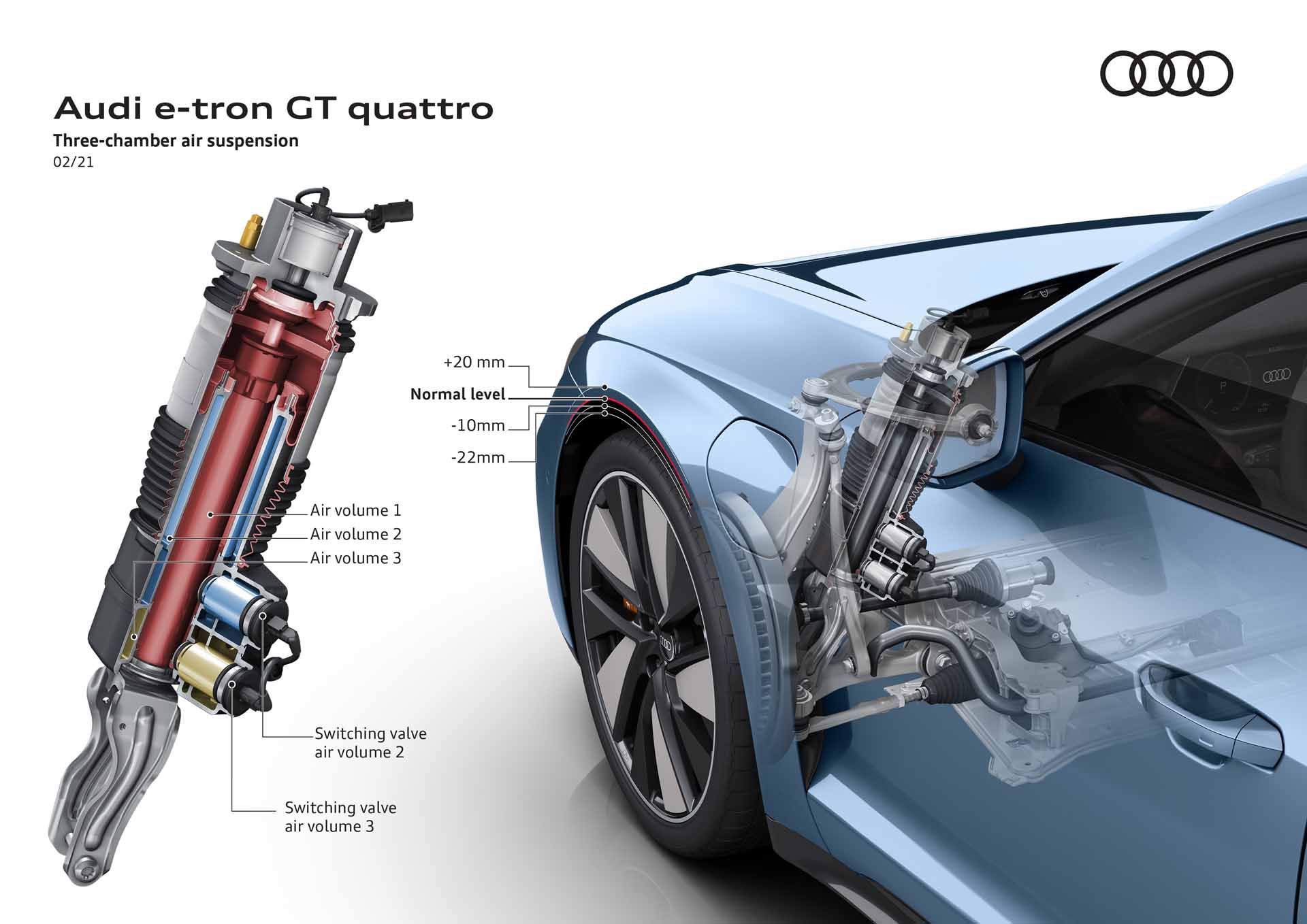

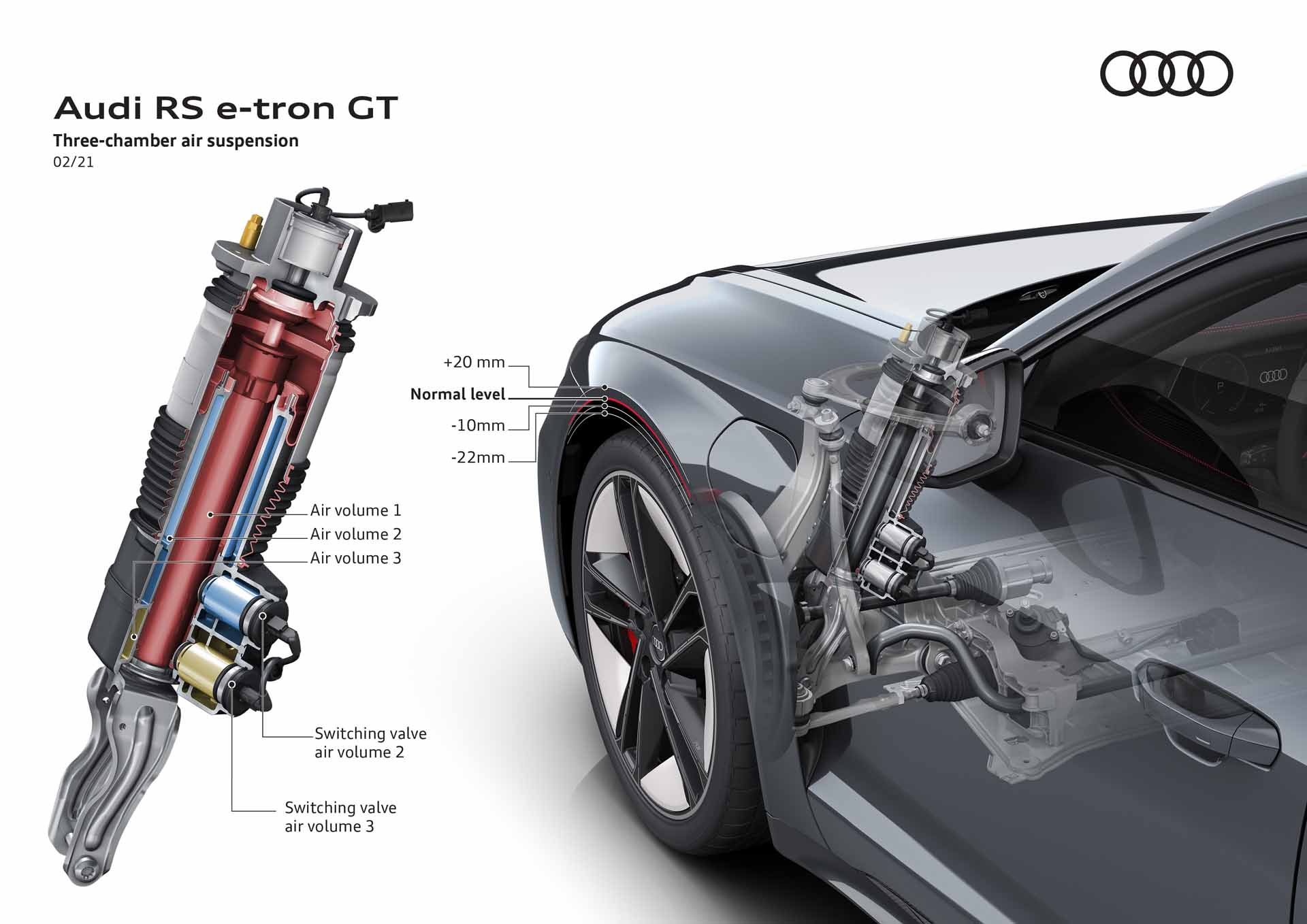

Three-chamber air suspension

Wheels with design blades

Ceramic brake

Carbid brake

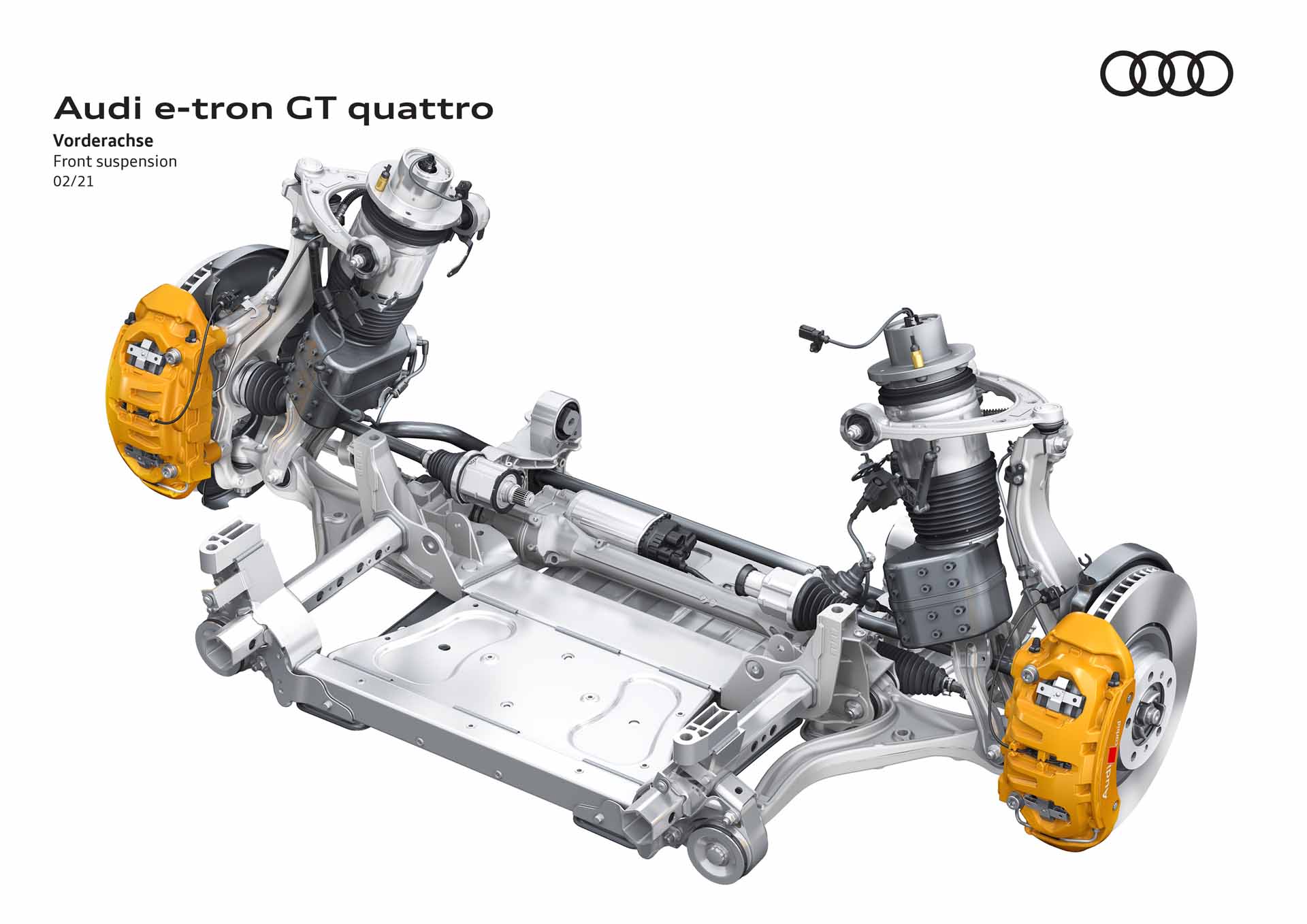

Front suspension

Front suspension with electric motor

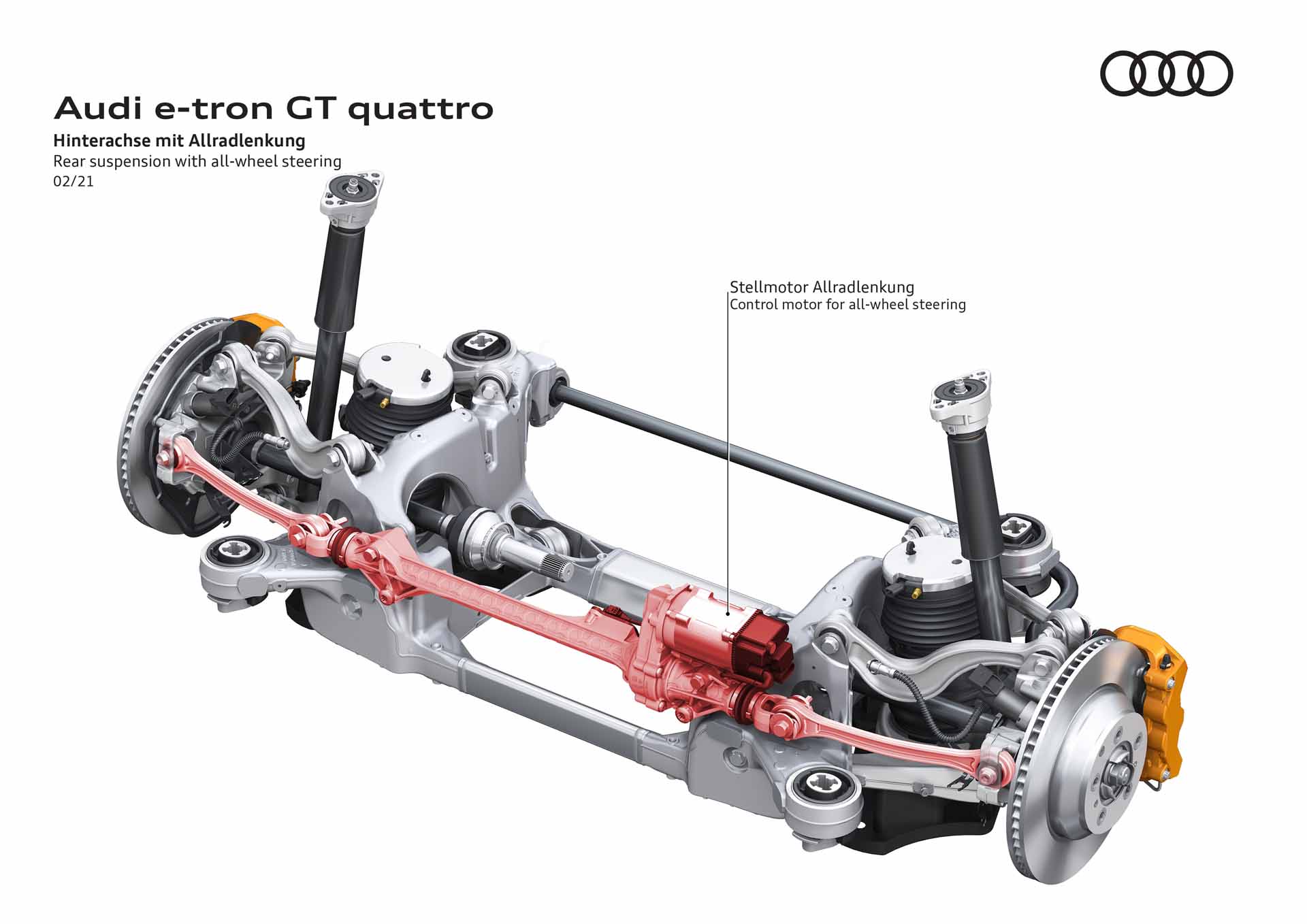

Rear suspension

Rear suspension with electric motor

Rear suspension with all-wheel steering

Suspension

Suspension with electric motors

Drivetrain

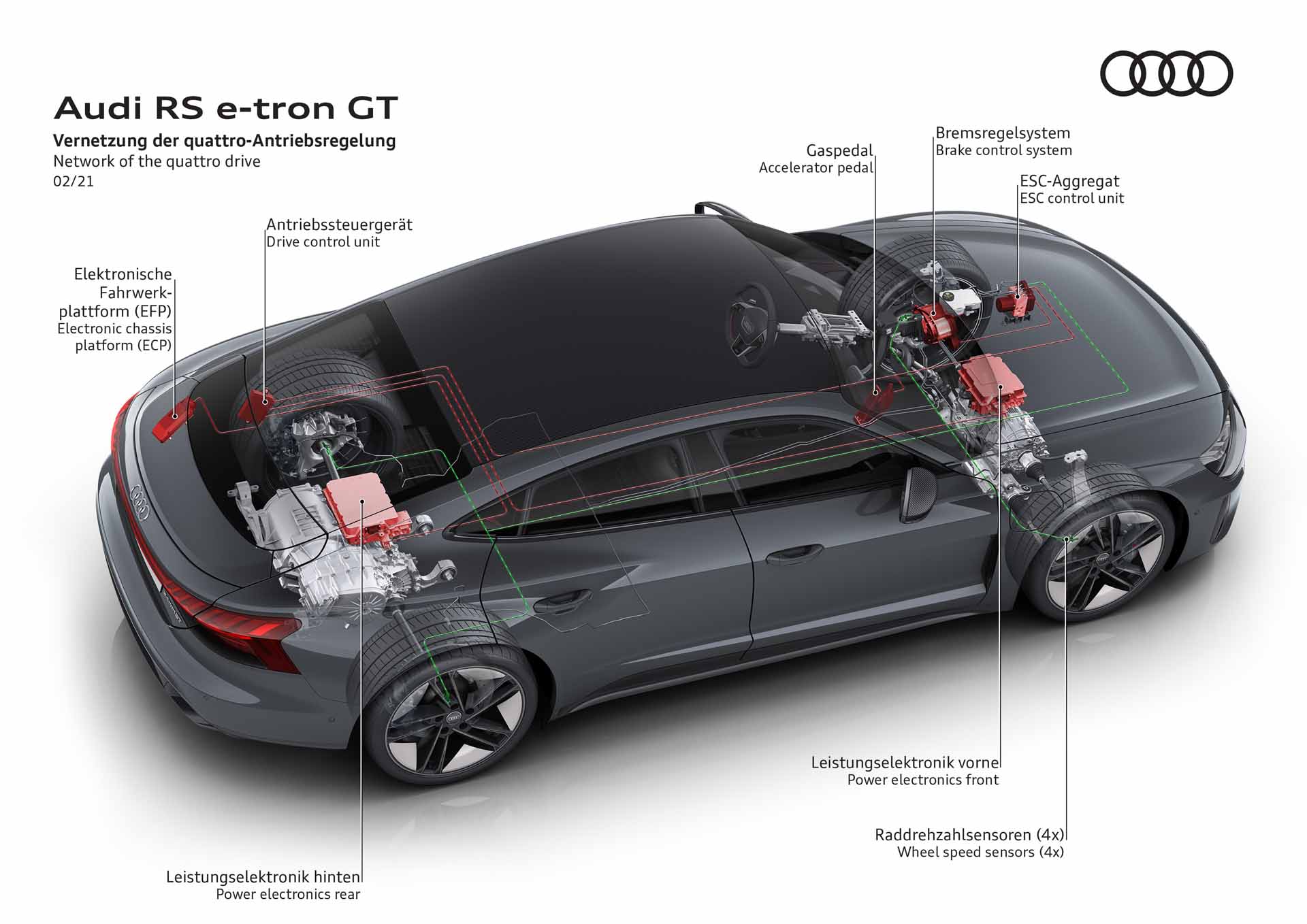

Network of the quattro drive

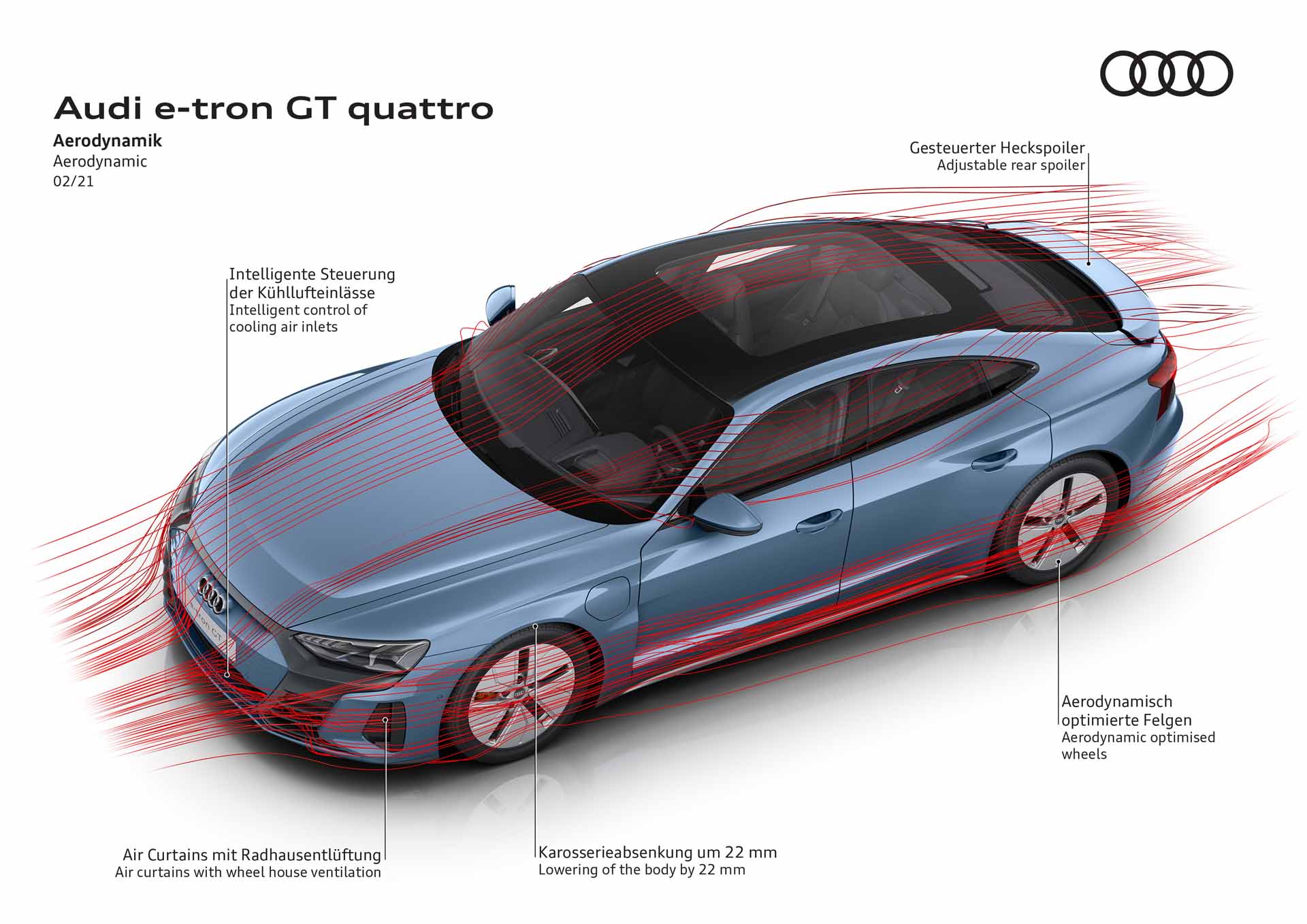

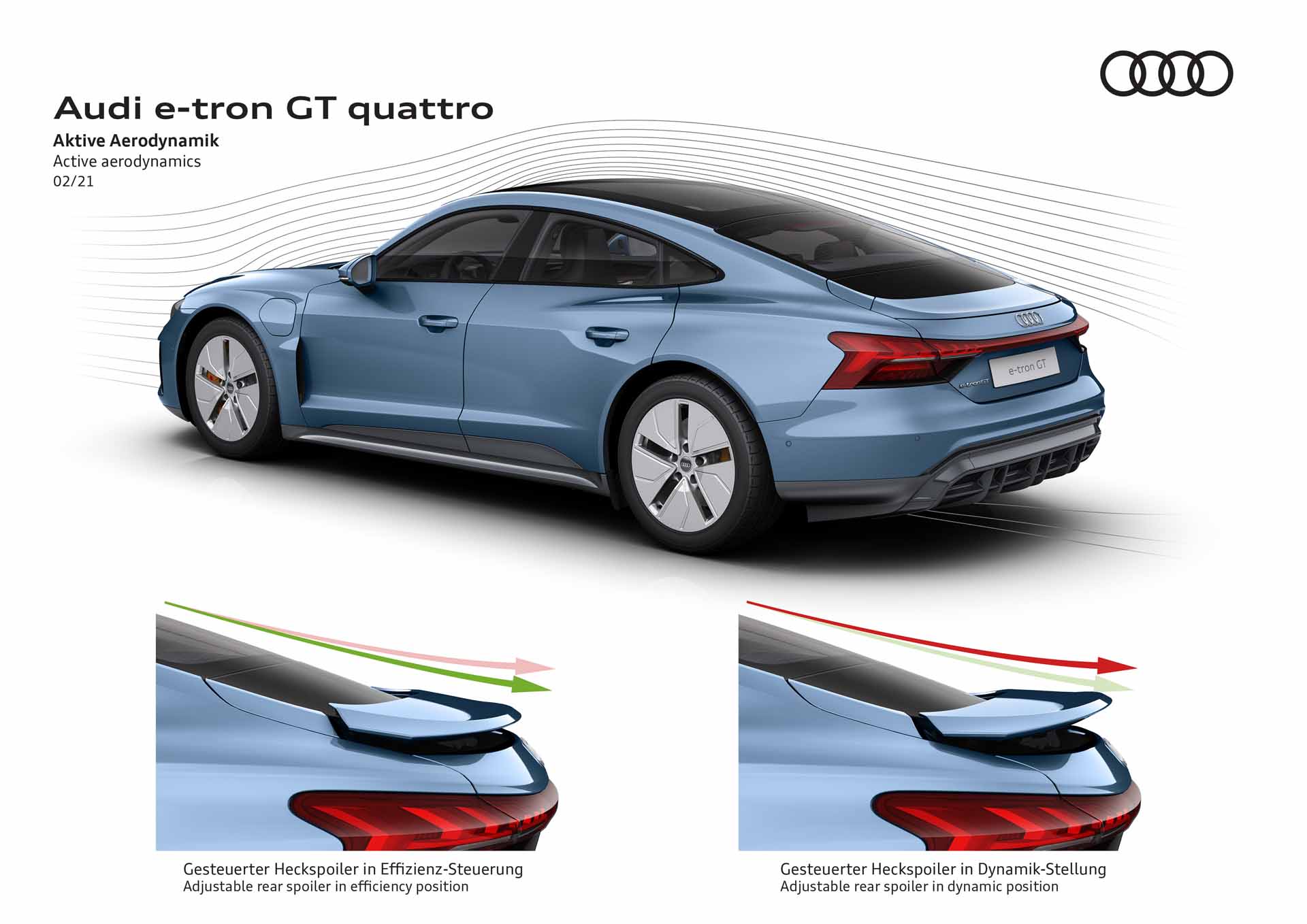

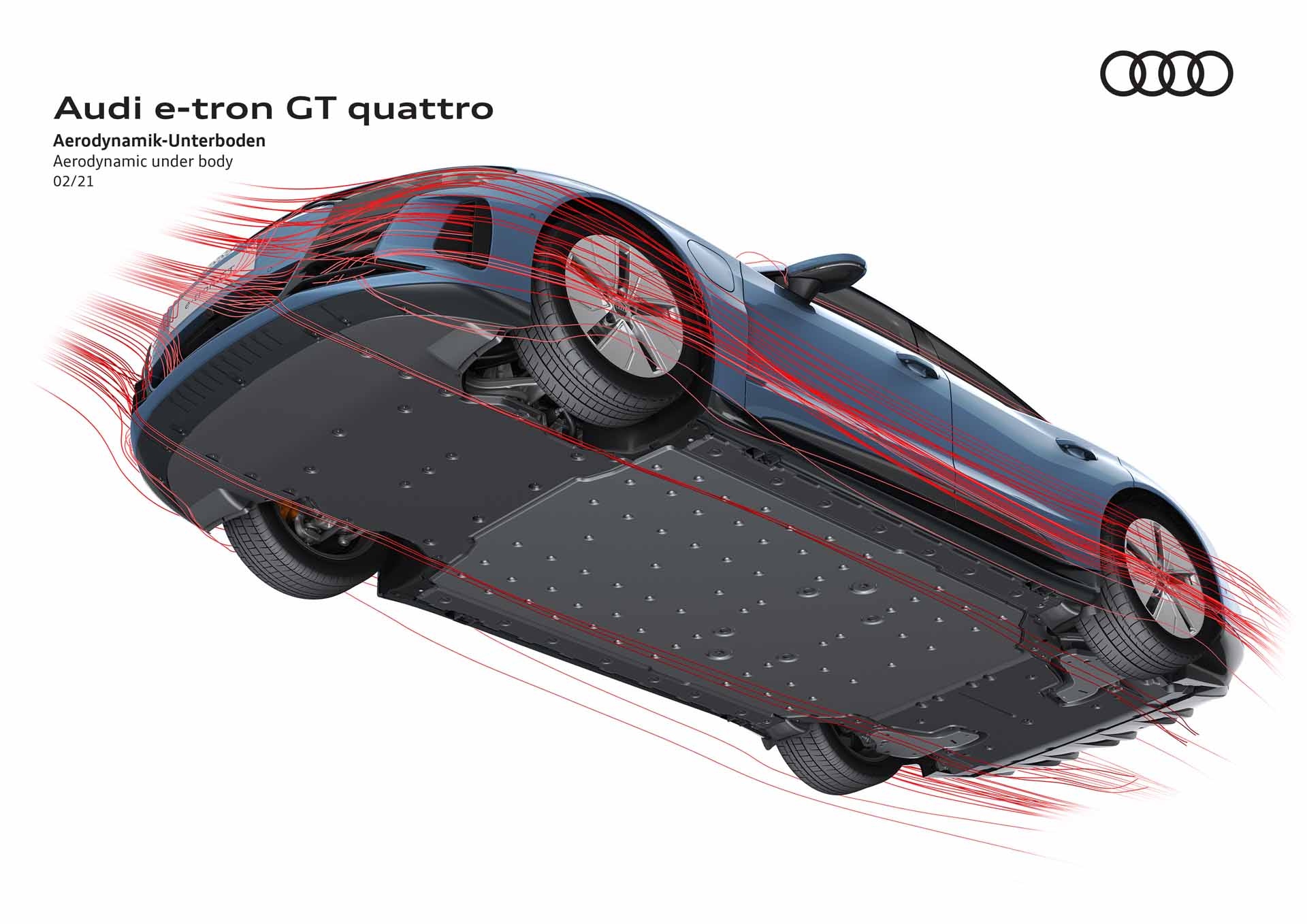

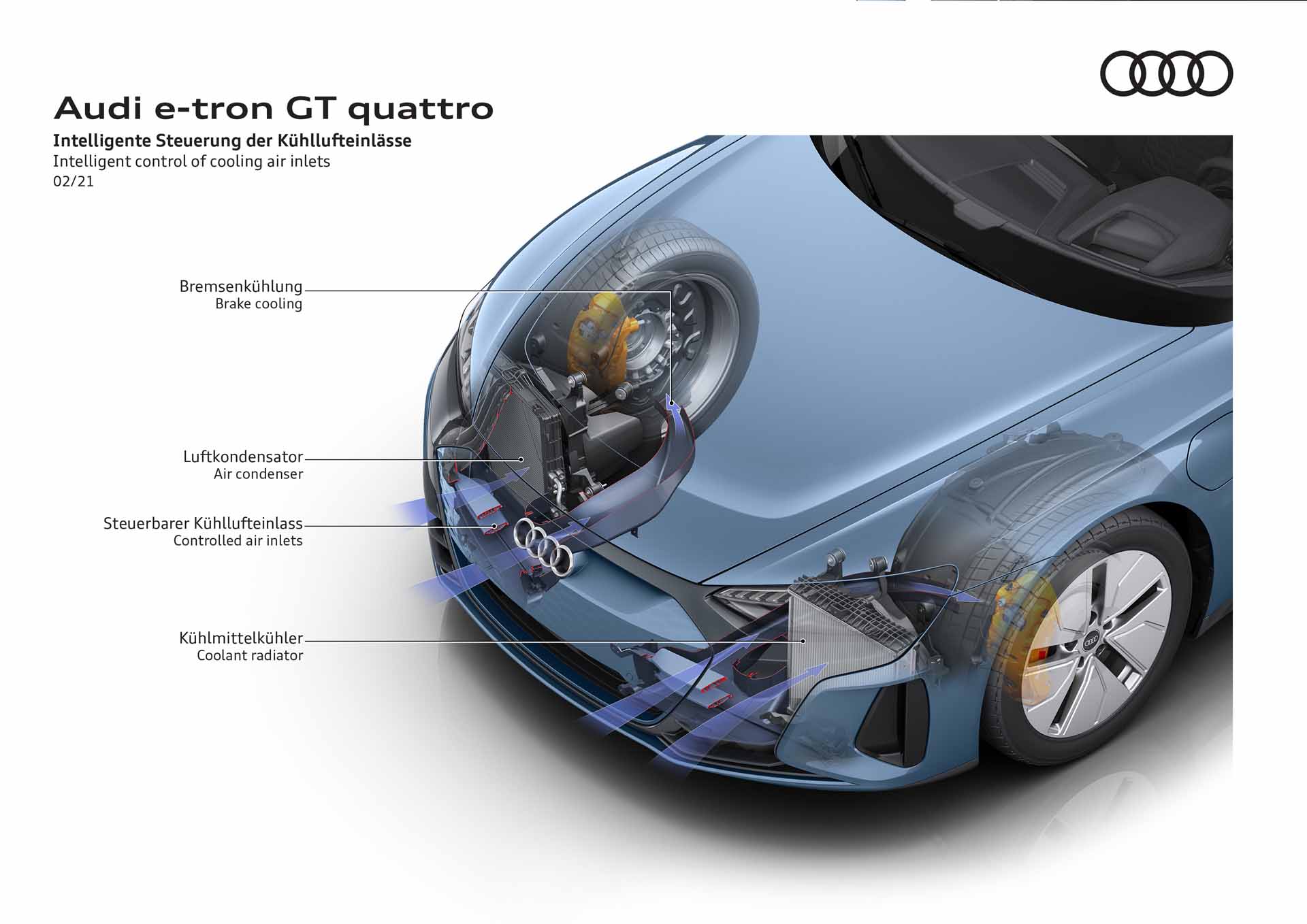

Aerodynamic

Active aerodynamics

Aerodynamic under body

Intelligent control of cooling air inlets

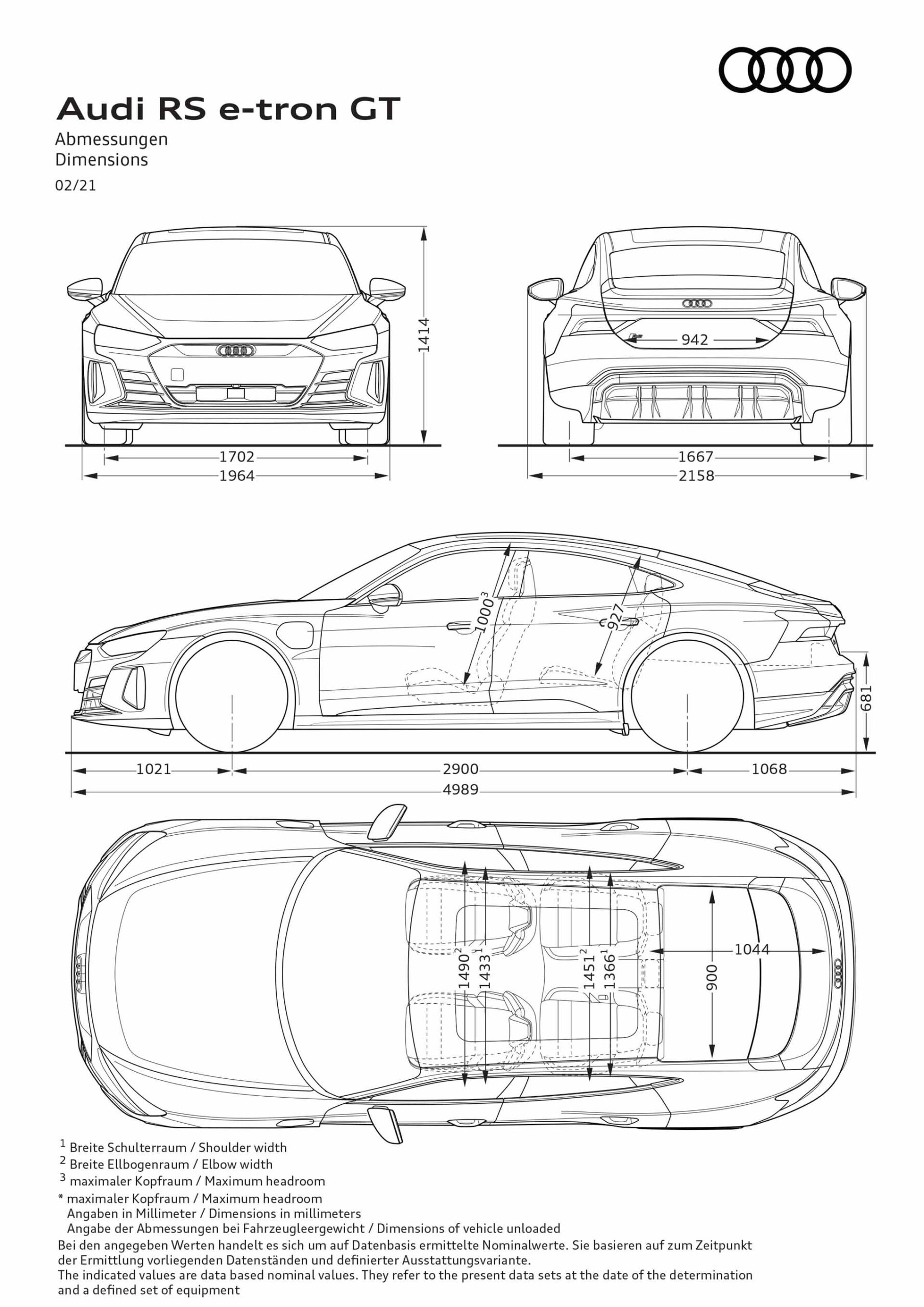

RS e-tron GT

Voir aussi mon bref essai dans l’article sur les Audi Electric Days by Autosphere.

Prototype

Extérieur

Intérieur

Technique

Suspension

Network of the quattro drive

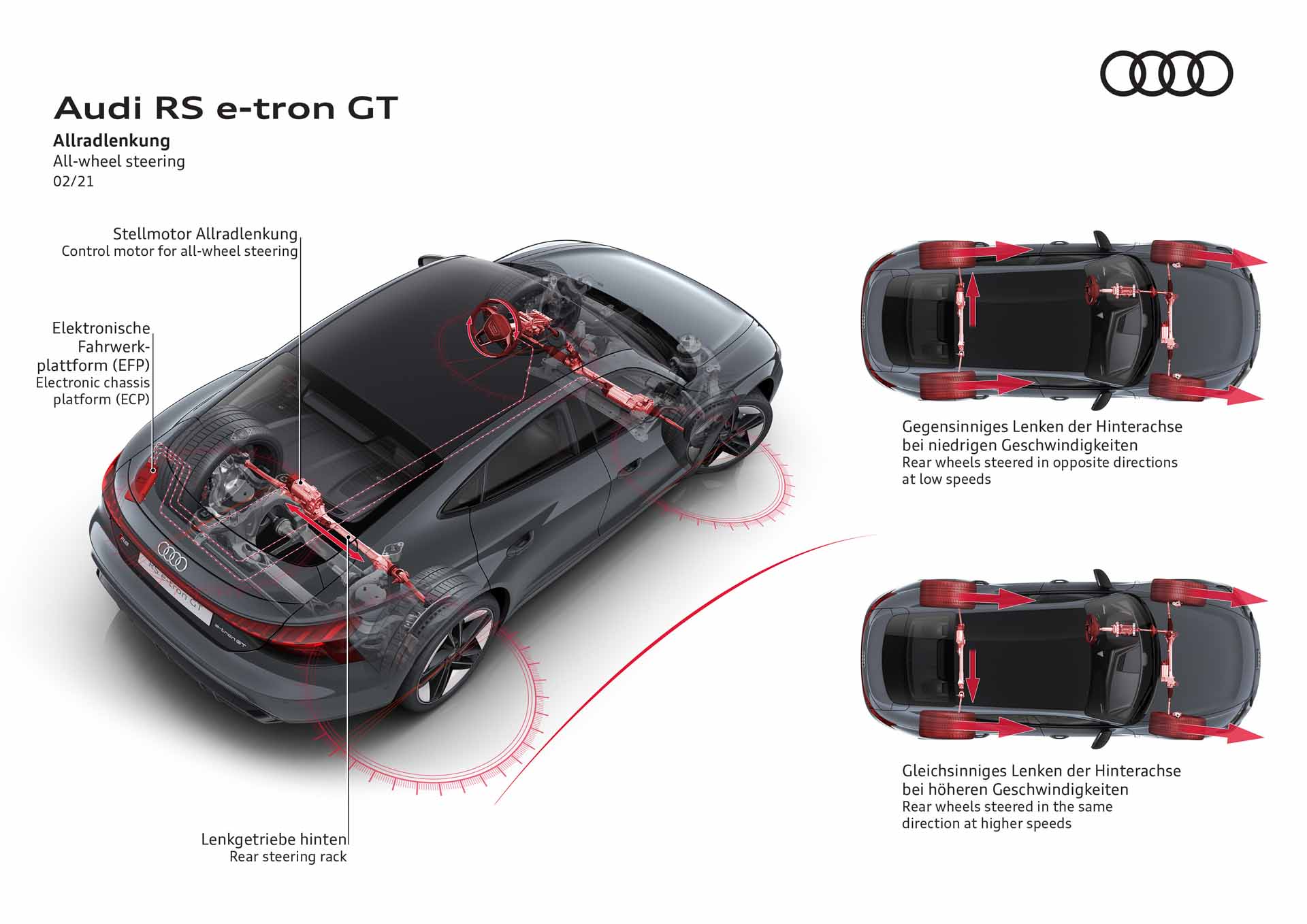

All-wheel steering

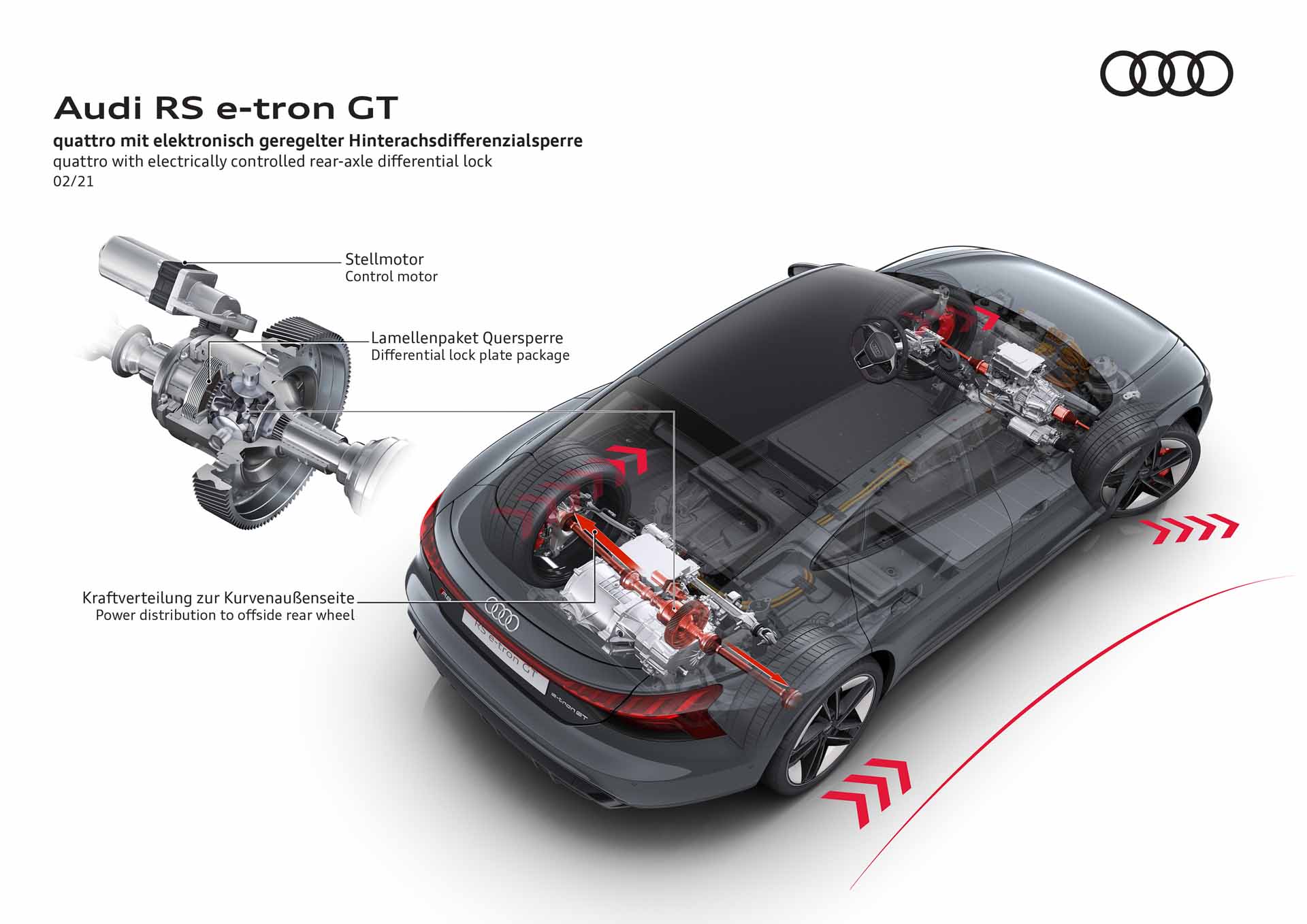

quattro with electrically controlled rear-axle differential lock

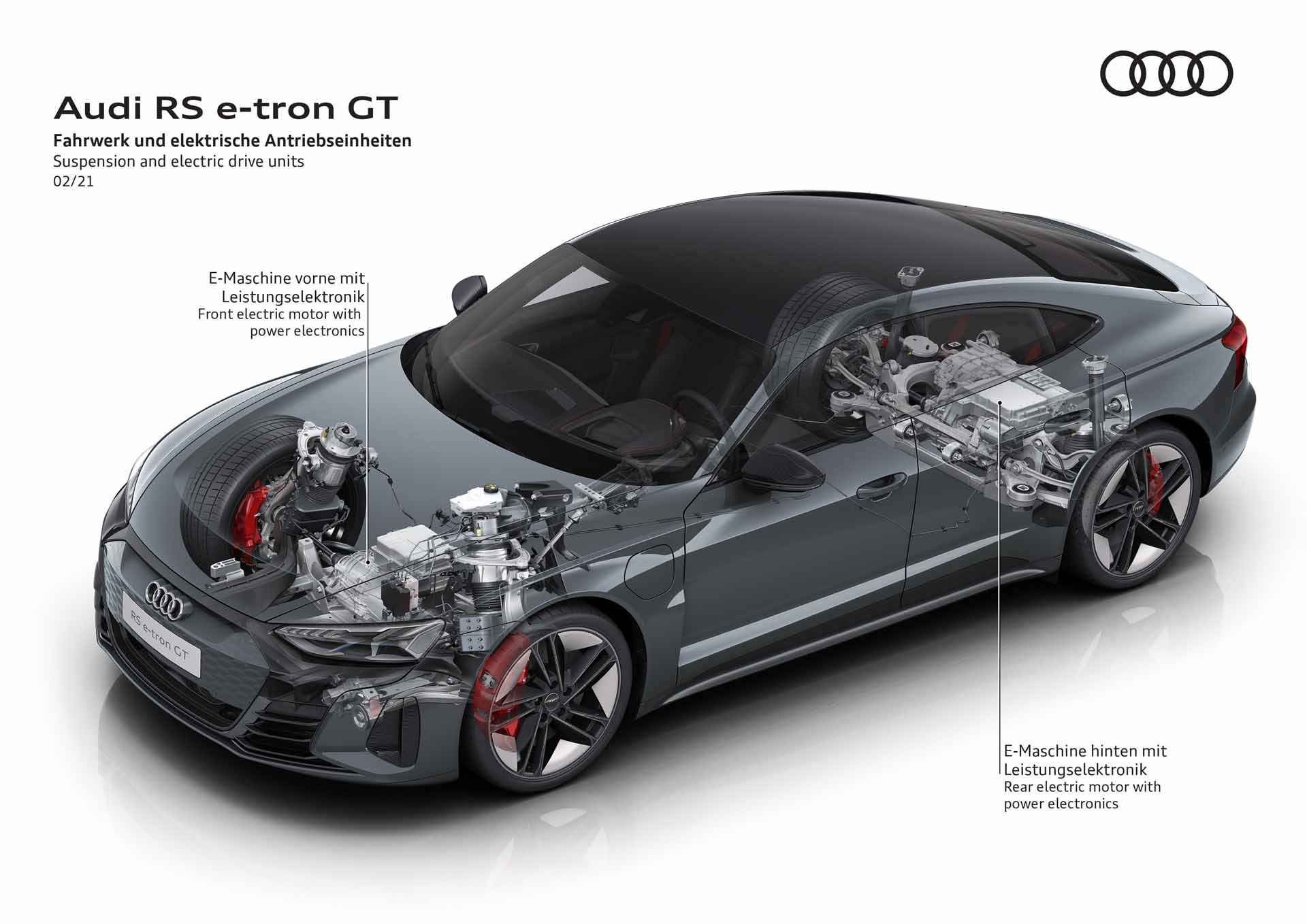

Suspension and electric drive units

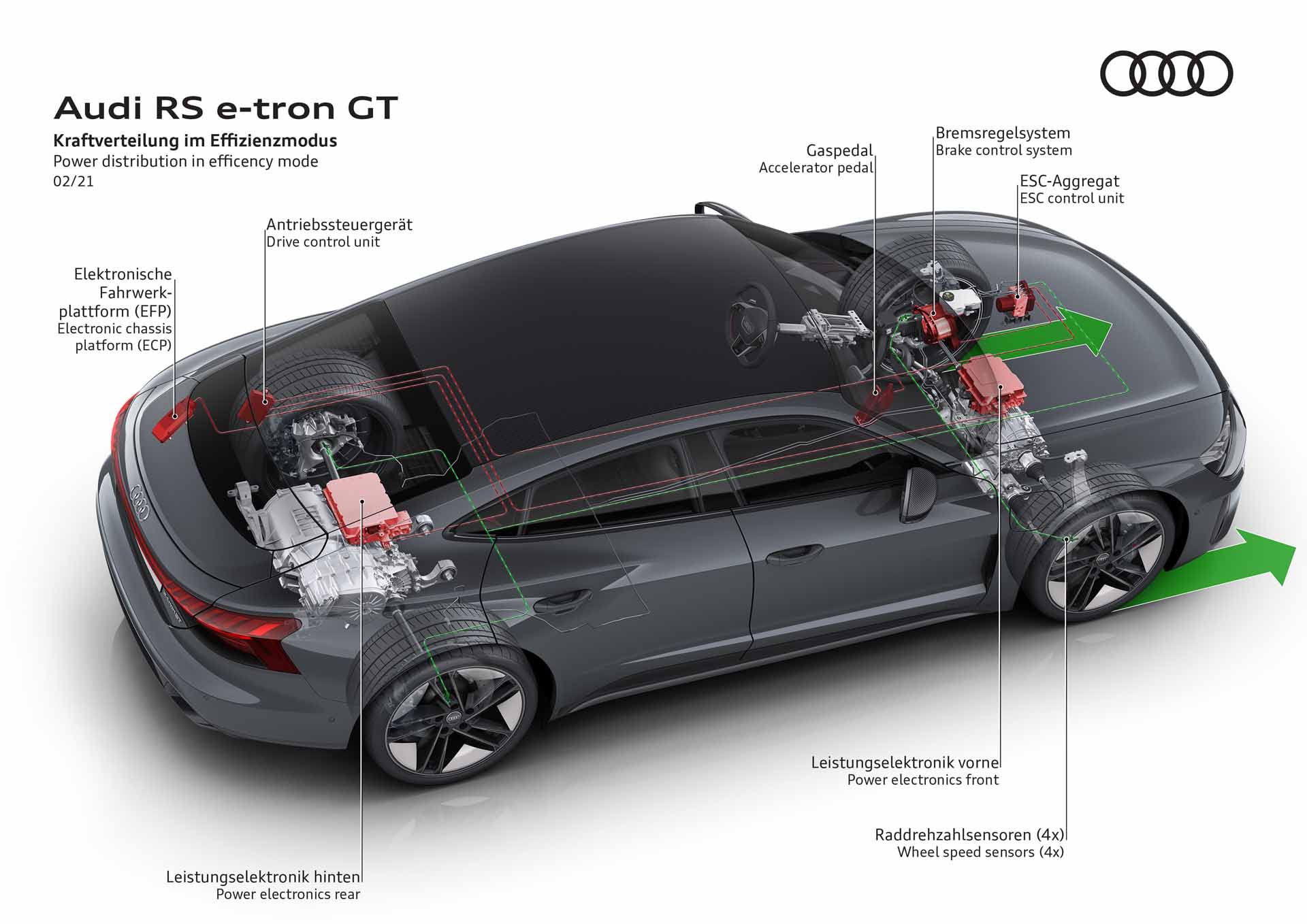

Power distribution in efficency mode

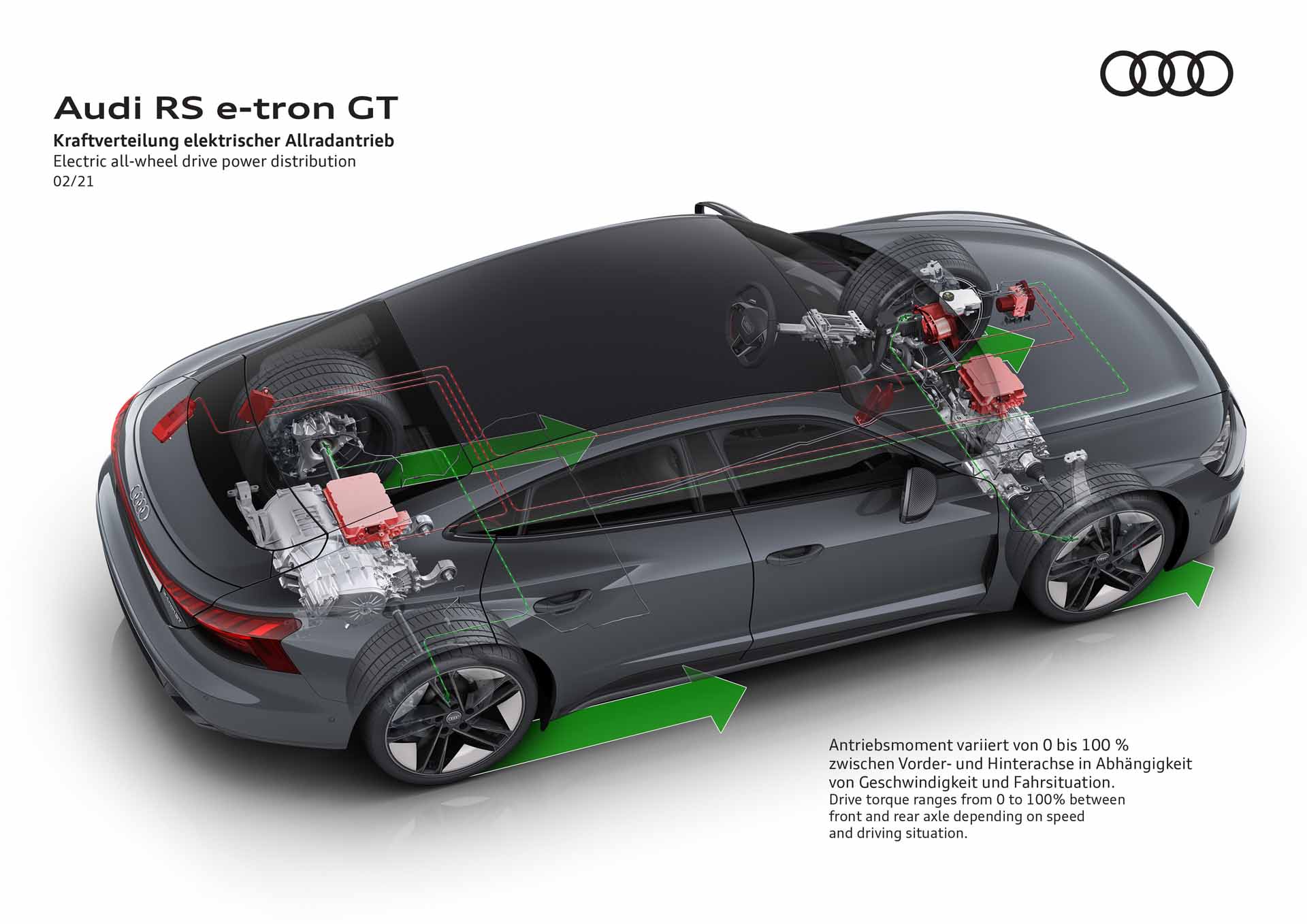

Electric all-wheel drive power power distribution

Recuperation

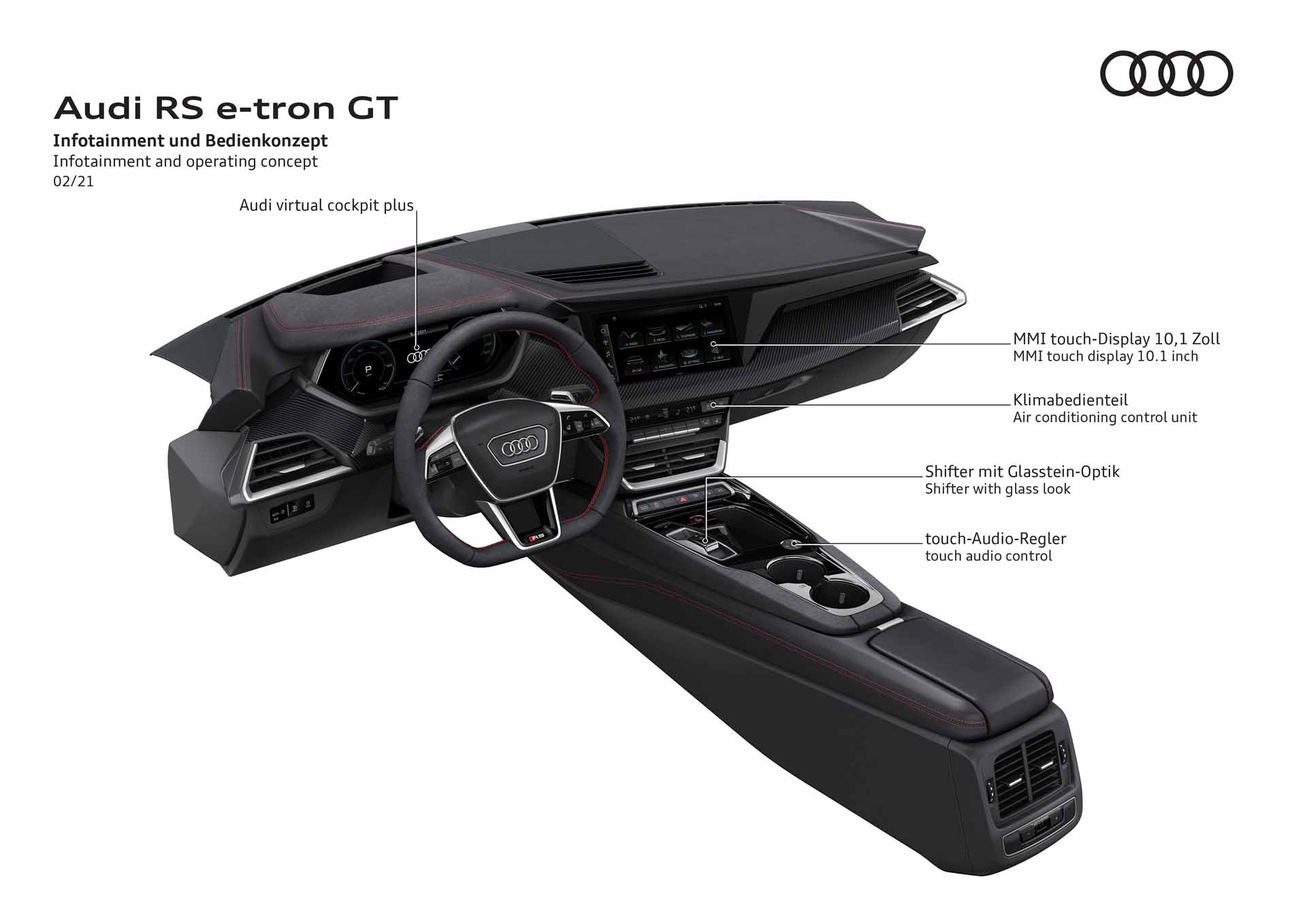

Infotainment and operating concept

Infotainment and operating concept

Interior

Axle specific distribution of driving torque with low grip levels

Axle specific distribution of driving torque with low grip levels

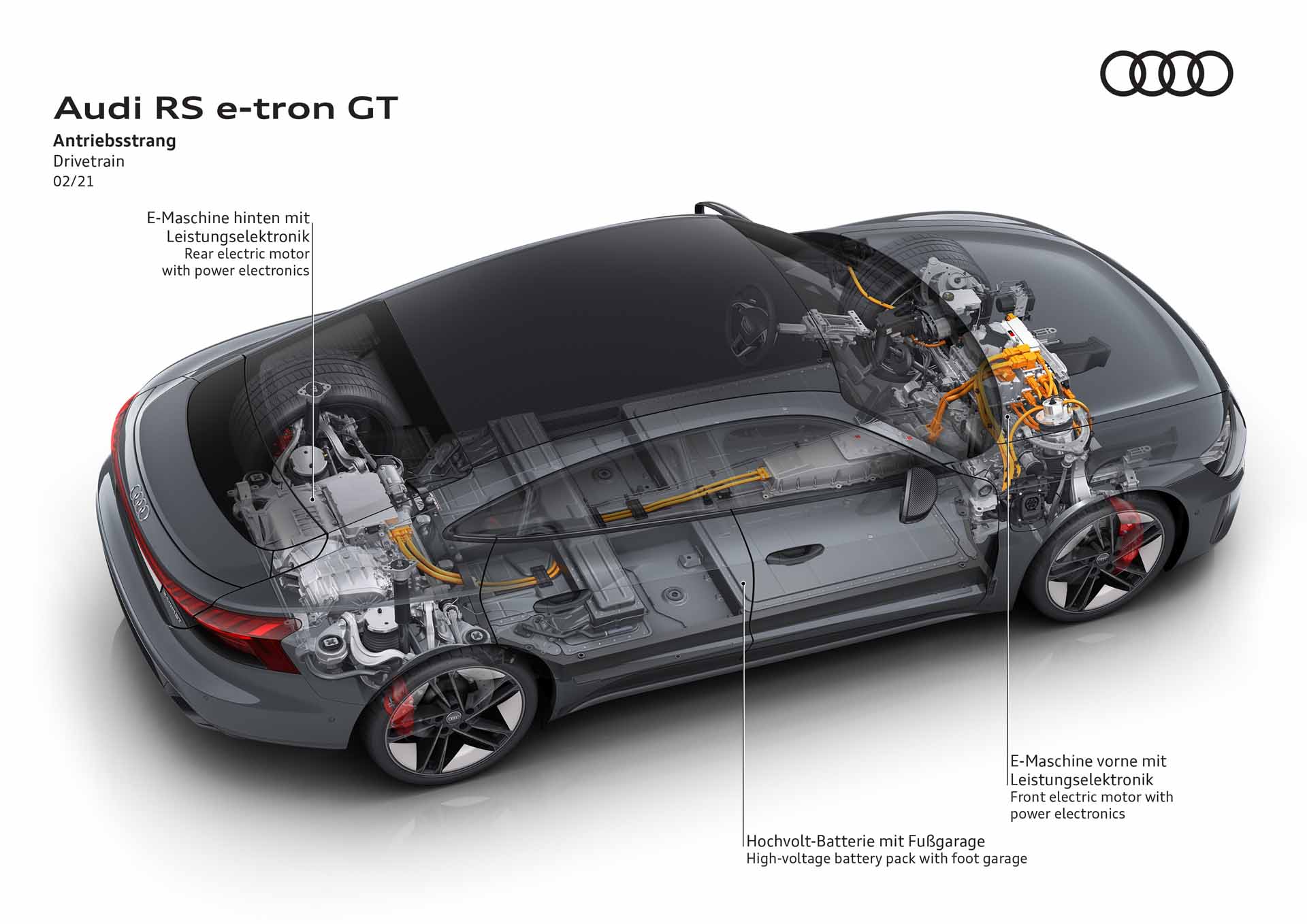

Drivetrain

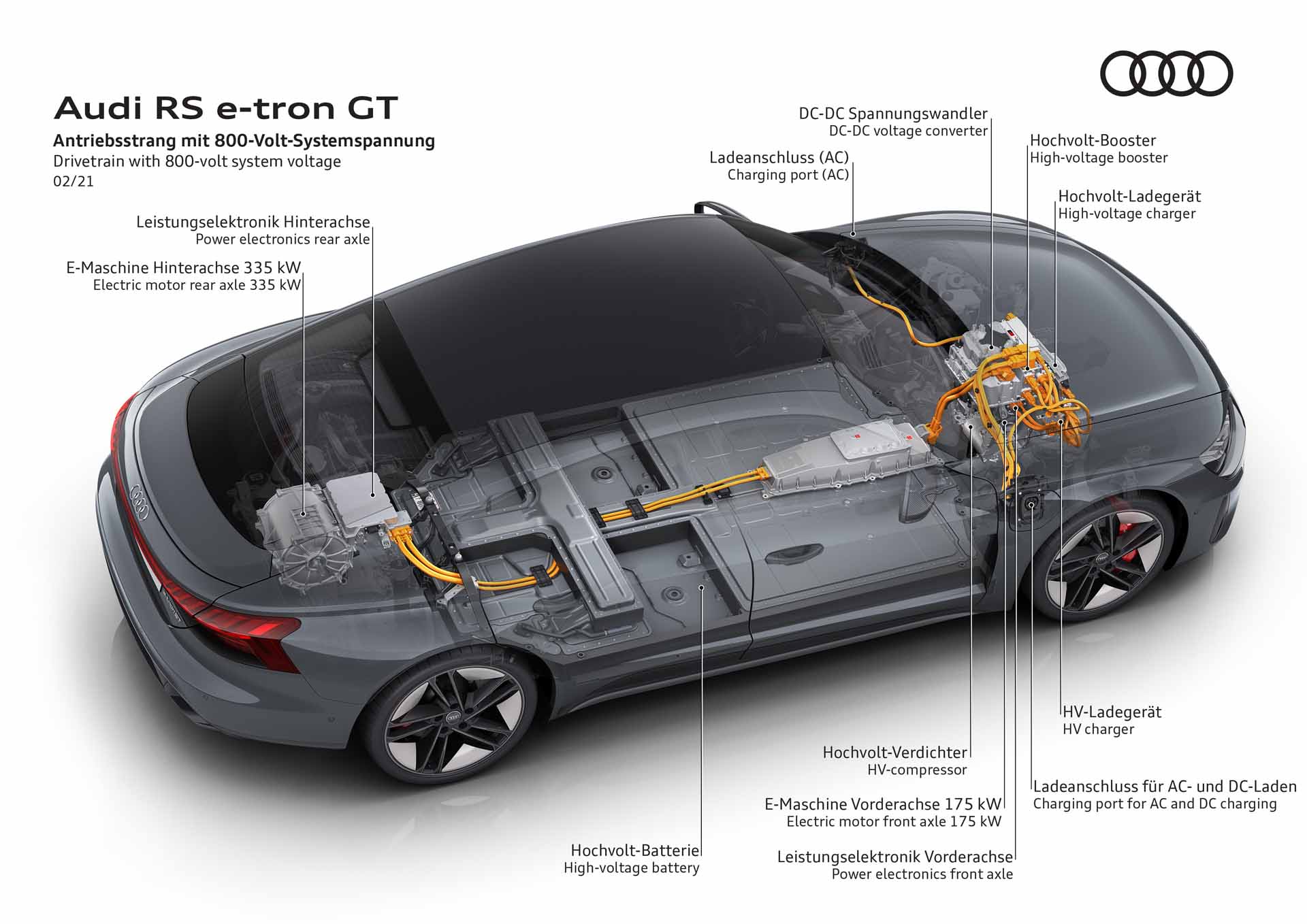

Drivetrain with 800-volt system voltage

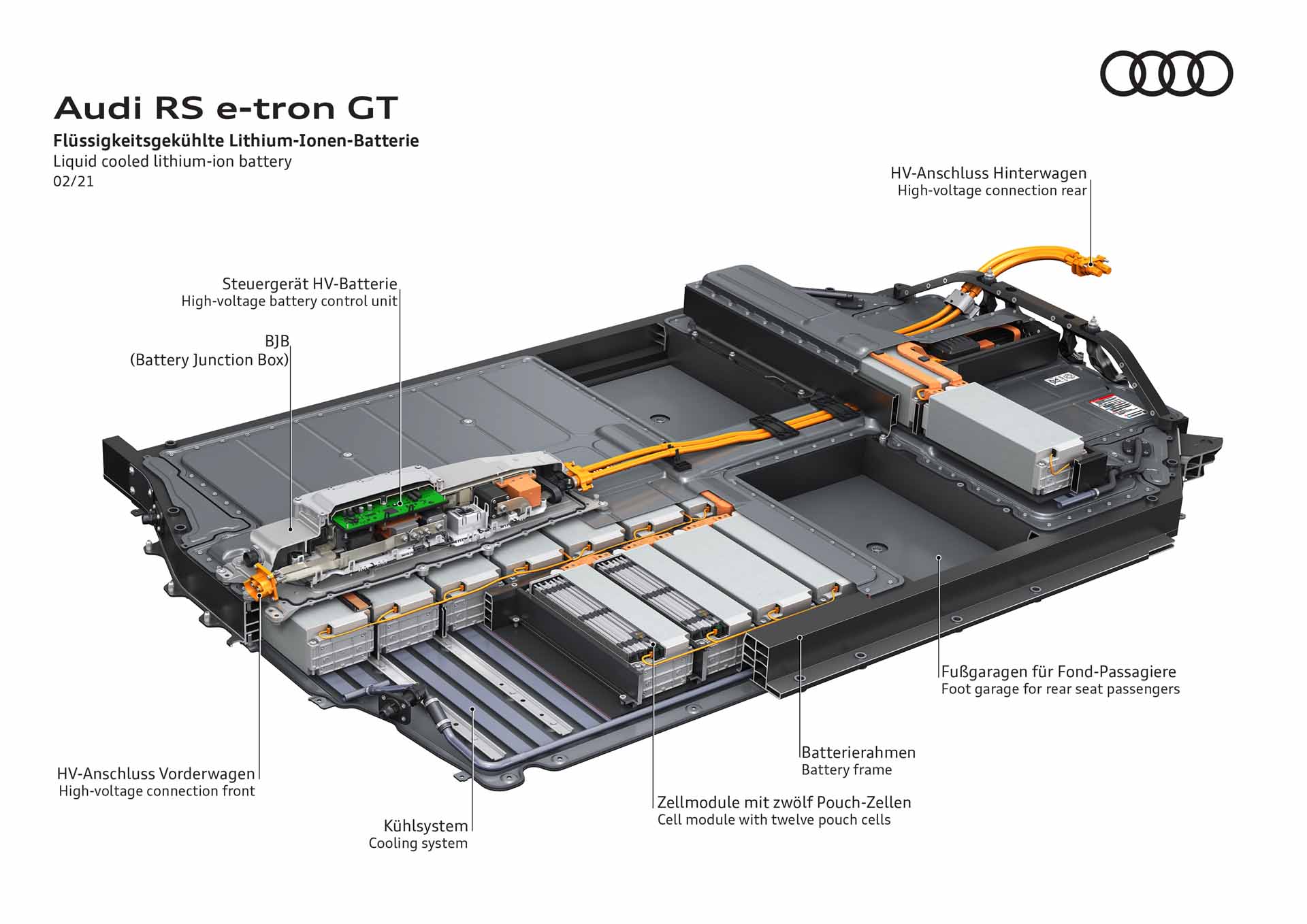

Liquid cooled lithium-ion battery

Liquid cooled lithium-ion battery

Integration of the high-voltage battery in the body structure

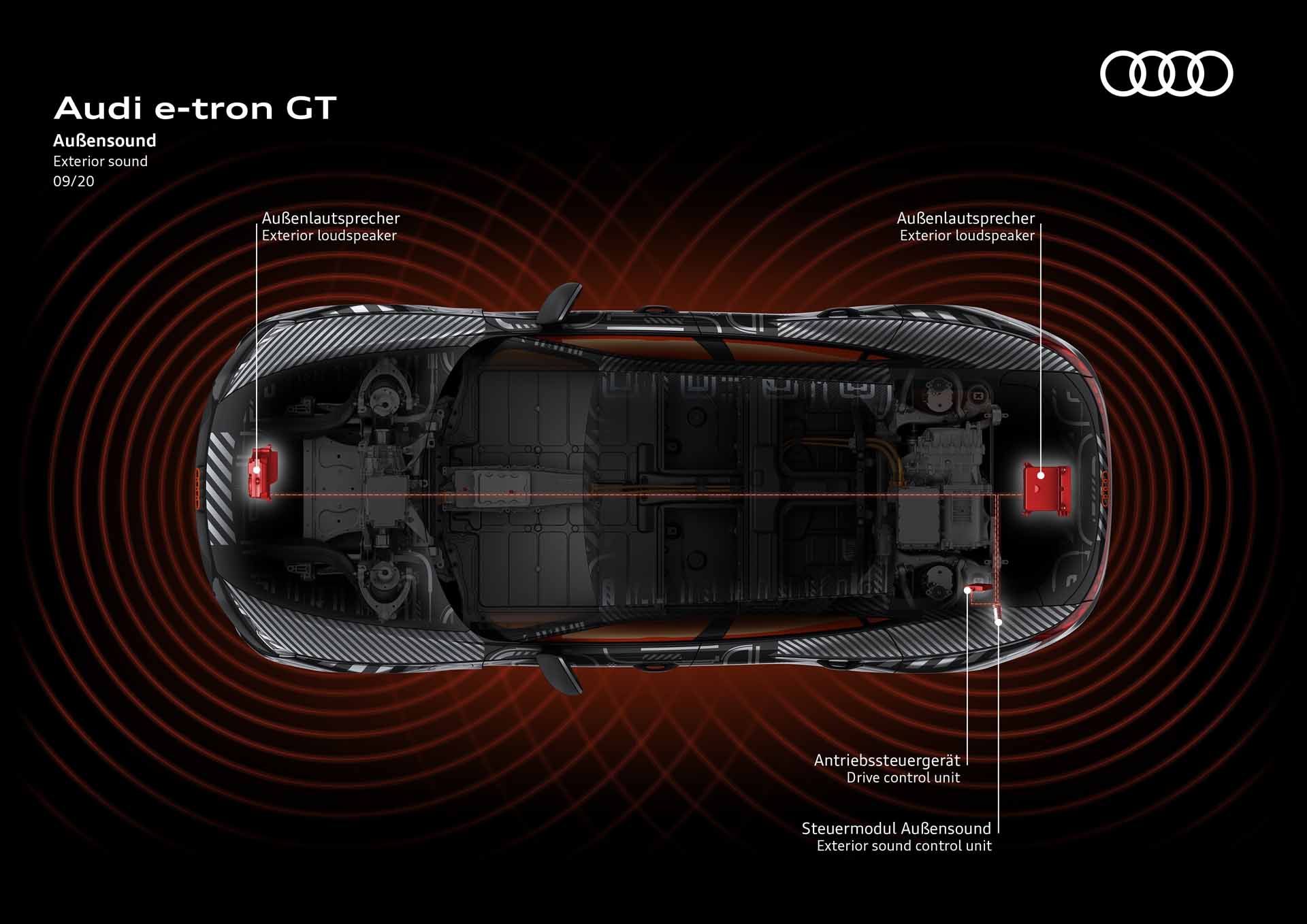

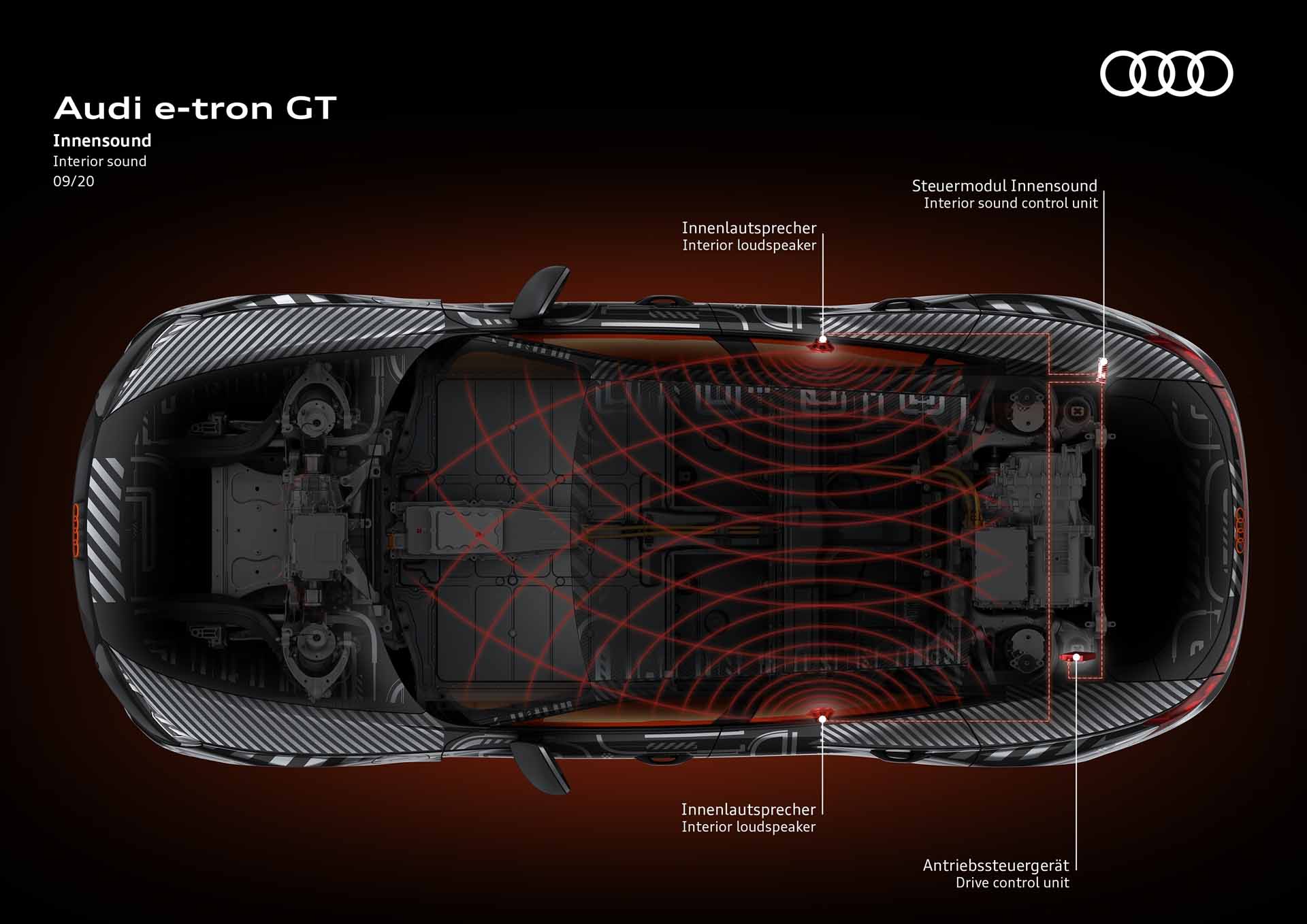

Interior and exterior sound

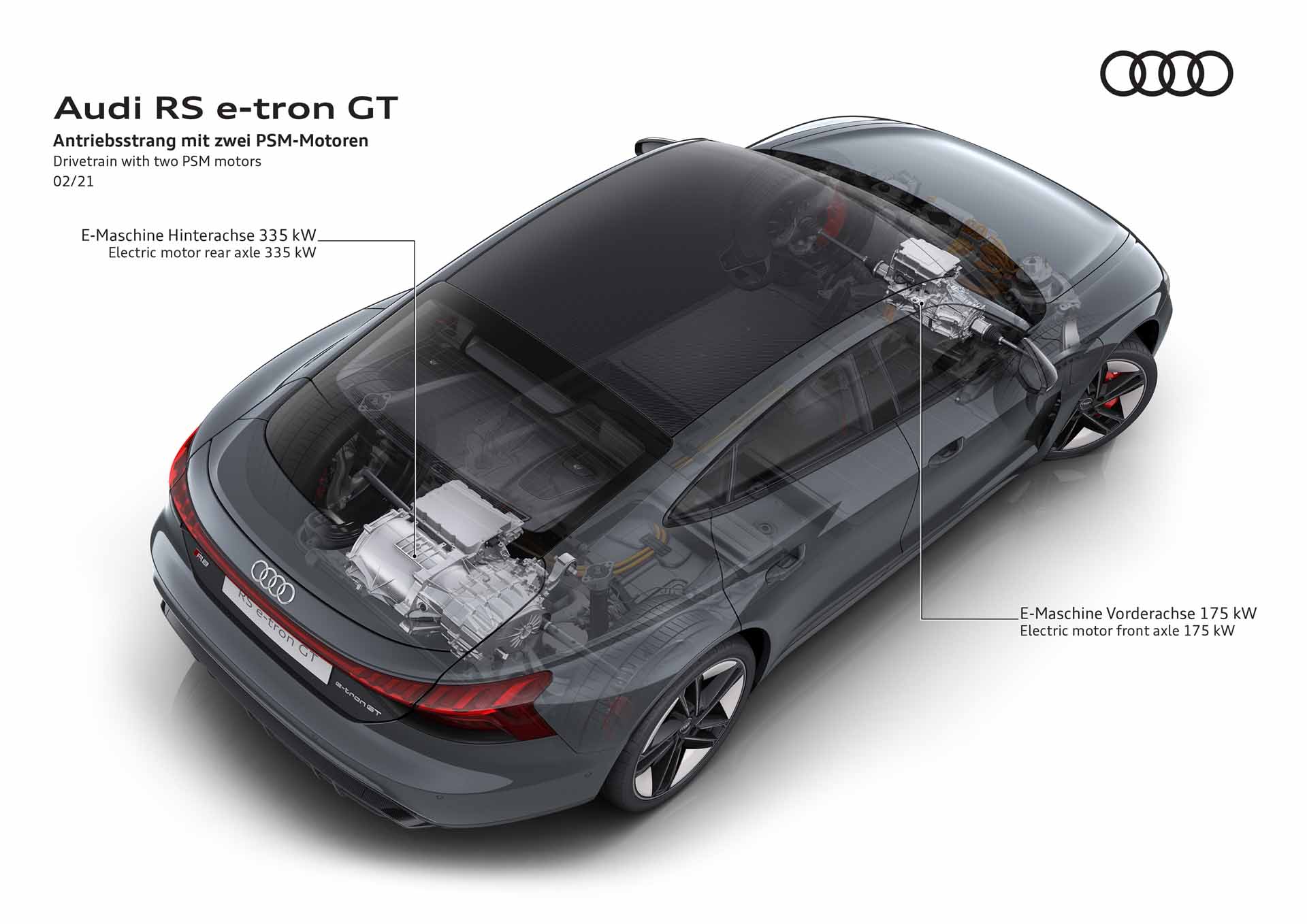

Drivetrain with two PSM motors

Drivetrain

18-way adjustable front seat

Drivetrain

Interior

Audi RS e-tron GT

Three-chamber air suspension

Three-chamber air suspension